AAA Products International Inc.

7114 Harry Hines Blvd.

Dallas, Texas 75235

214-357-3851

7114 Harry Hines Blvd.

Dallas, Texas 75235

214-357-3851

E-Series Coils

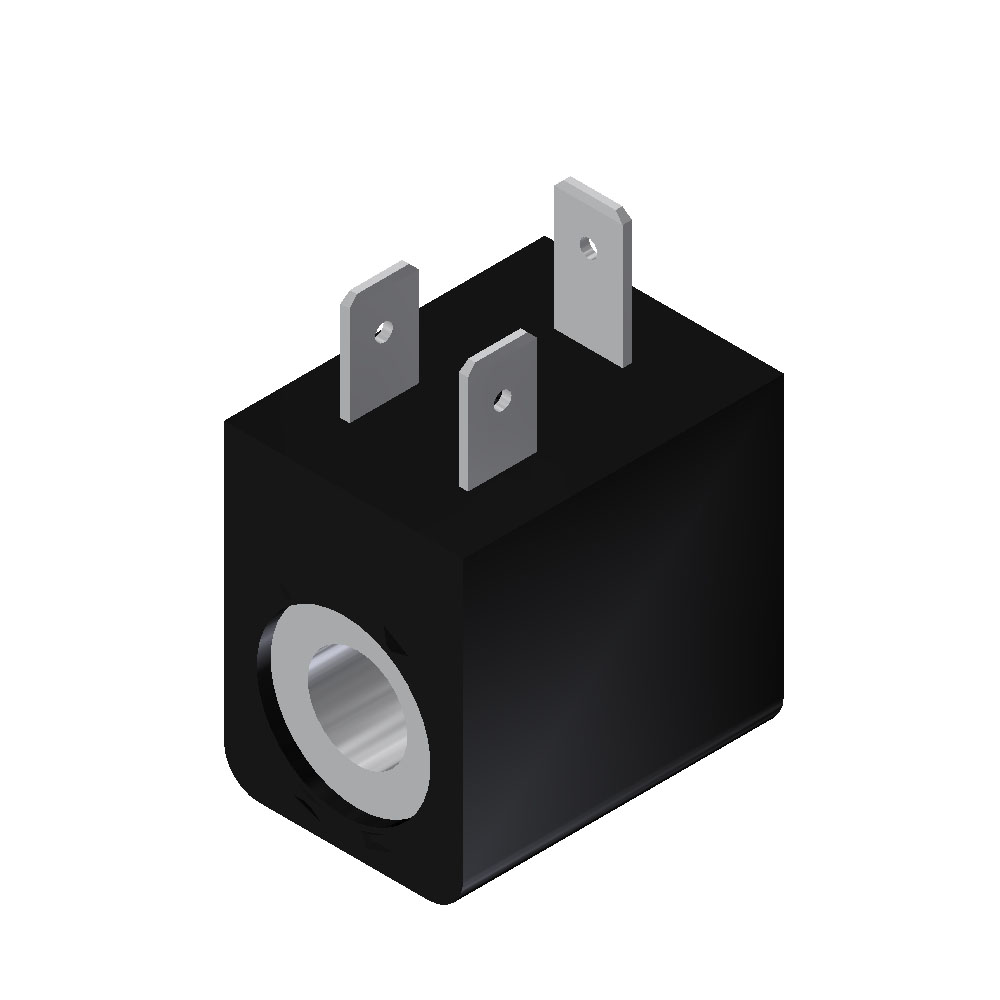

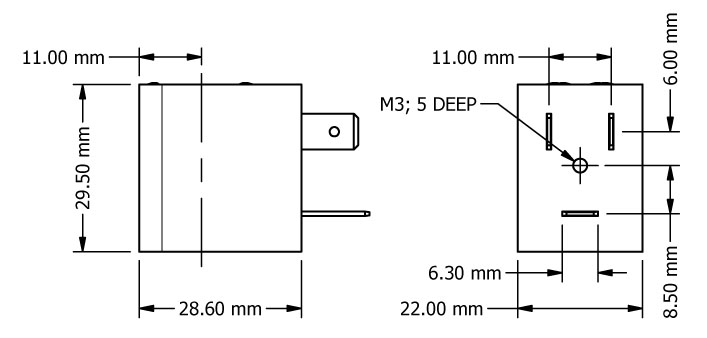

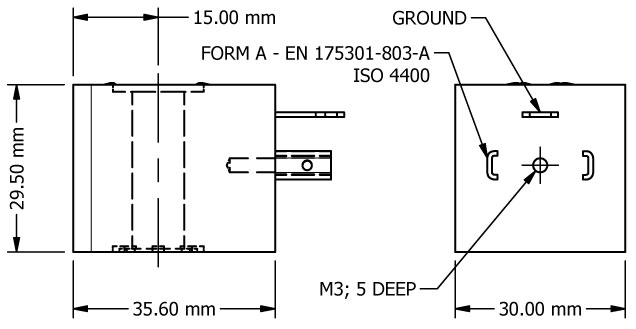

"E-Series" Coil - Standard

The standard coils are a DIN 43650-B style with a 11mm/Industrial Type B connector pin pattern (mini connector, 11 mm contact distance). DIN caps are ordered as a separate line item. Voltage must be specified when ordering. If no voltage is specified, then 120/60 is provided. Other voltages not shown below are available. Coil can be rotated in 90° increments on operator stem when space is available. An approved cap must be used when connecting to an electrical source. The longer tab is the ground (earth). Either shorter tab can be connected to hot (+) and the other connected to neutral (-).

| Voltage | Pick-Up | Holding | Resistance | Spare Coil | |

|---|---|---|---|---|---|

| 24 volts, 50/60 Hz | 7.1 VA | 5.8 VA | 27.4 ohms |  | |

| 48 volts, 50/60 Hz | 7.7 VA | 6.2 VA | 97.9 ohms | ||

| 110 volts, 50 Hz, 120 volts, 60 Hz | 7.8 VA | 6.3 VA | 619 ohms | ||

| 240 volts, 50/60 Hz | 7.8 VA | 6.3 VA | 3400 ohms | ||

| 12 volts D-C | 4.6 Watts | 27.4 ohms | |||

| 24 volts D-C | 4.8 Watts | 97.9 ohms | |||

| 60 volts D-C | 4.3 Watts | 619 ohms |

Molding Material: Thermoplastic.

Ambient Temperature: -20°C to +50°C.

Relative Duty Cycle: 100%.

Degree of Protection: IP65 with connector (IP67 possible with accessories).

Certifications: This coil carries the UL certificate of compliance both the standard and Canadian certification. A copy of the certification is available here. The rating only applies to the coil and not the entire valve.

Voltage Tolerance: ± 10%.

Resistance Tolerance: ± 8% at 20°C.

Insulation Class: F

Ambient Temperature: -20°C to +50°C.

Relative Duty Cycle: 100%.

Degree of Protection: IP65 with connector (IP67 possible with accessories).

Certifications: This coil carries the UL certificate of compliance both the standard and Canadian certification. A copy of the certification is available here. The rating only applies to the coil and not the entire valve.

Voltage Tolerance: ± 10%.

Resistance Tolerance: ± 8% at 20°C.

Insulation Class: F

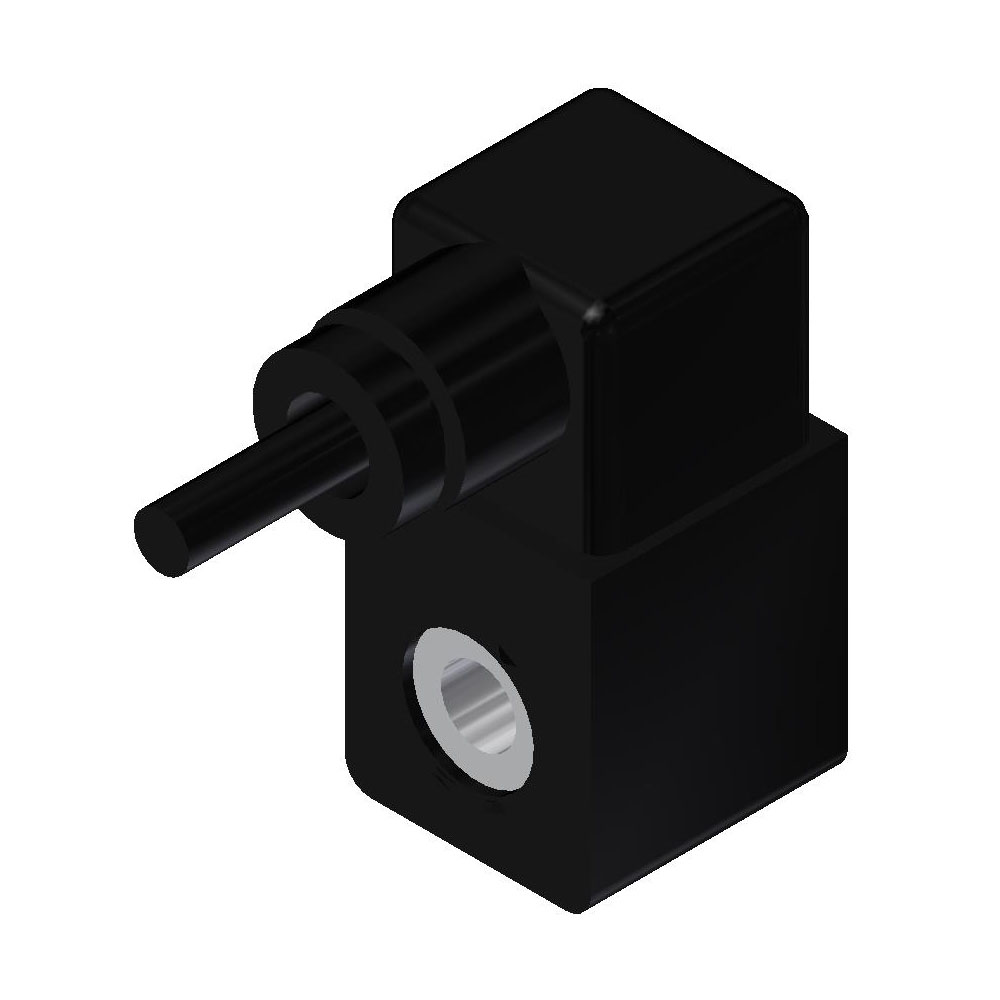

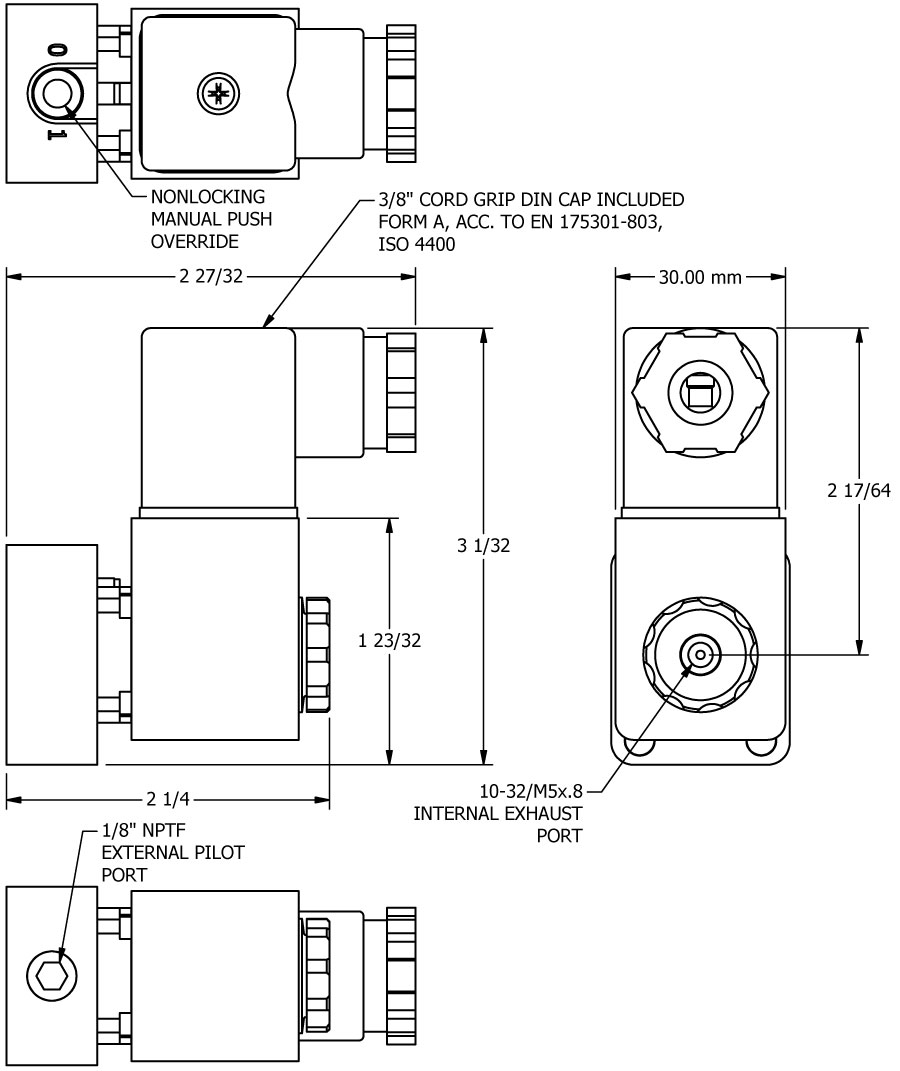

"E-Series" Coil - Option A - Intrinsically Safe

When related to solenoid valves, intrinsic safety means that the coil's current draw and resulting temperature is held to such a low level (when used with an approved safety barrier) that the valve no longer has the capability of igniting a mixture of flammable or combustible material, either during normal operation or under fault conditions. Typically, they are used in situations where fire and explosive hazards exist due to the presence of flammable gases, vapors or liquids, combustible dusts or easily ignitable fibers. Intrinsically safe coils and operators are sold as a matched set and must be ordered as V-564 (individual components are not available). Solenoid operator maximum pressure is 115 psi.

These operators are equipped with the standard V-562 nut but can be ordered with a V-567W bronze muffler nut (option L) or a V-562 side exhaust nut (option C).

These 24 VDC coils are approved according to EN 50 020 respectively DIN VDE 0170/0171 part 5 for hazardous location. Class I, groups A, B, C and D; Class II, groups E, F and G; Class III. This coil is an ISO 4400 DIN style pin pattern. A non-indicator, cord grip style cap is provided. A copy of the certification is available here. An approved cap (included) must be used when connecting to an electrical source. The longer tab is the ground (earth). Either shorter tab can be connected to hot (+) and the other connected to neutral (-).

These operators are equipped with the standard V-562 nut but can be ordered with a V-567W bronze muffler nut (option L) or a V-562 side exhaust nut (option C).

These 24 VDC coils are approved according to EN 50 020 respectively DIN VDE 0170/0171 part 5 for hazardous location. Class I, groups A, B, C and D; Class II, groups E, F and G; Class III. This coil is an ISO 4400 DIN style pin pattern. A non-indicator, cord grip style cap is provided. A copy of the certification is available here. An approved cap (included) must be used when connecting to an electrical source. The longer tab is the ground (earth). Either shorter tab can be connected to hot (+) and the other connected to neutral (-).

Molding Material: Thermoset resin.

Ambient Temperature: -20°C to +50°C.

Internal Diameter Orifice: 0.8mm

Relative Duty Cycle: 100%.

Degree of Protection: IP65 with connector.

Certifications: This coil carries the following certificate of compliance. The rating only applies to the coil/operator and not the entire valve.

Insulation Class: F

Electrical Characteristics: 21.6 - 28 VDC

"E-Series" Coil - Option H - High Temperature

The high temperature coils utilize a Form A/ISO 4400 DIN style connection (DIN 43650-A, 18 mm contact distance) with one ground tab and two voltage tabs. DIN caps are ordered as a separate line item. The coil is 30mm wide. Coil can be rotated in 45° increments on operator stem when space is available. An approved cap must be used when connecting to an electrical source. The longer tab is the ground (earth). Either shorter tab can be connected to hot (+) and the other connected to neutral (-).

| Voltage | Pick-Up | Holding | Resistance | Spare Coil | |

|---|---|---|---|---|---|

| 120 volts, 60 Hz | 6.8 VA | 741 ohms |   | ||

| 12 volts D-C | 4.5 Watts | 55 ohms |

Ambient Temperature: -20°C to +80°C.

Relative Duty Cycle: 100%.

Degree of Protection: IP65 with connector.

Voltage Tolerance: ± 10%.

Resistance Tolerance: ± 8% at 20°C.

Insulation Class: H

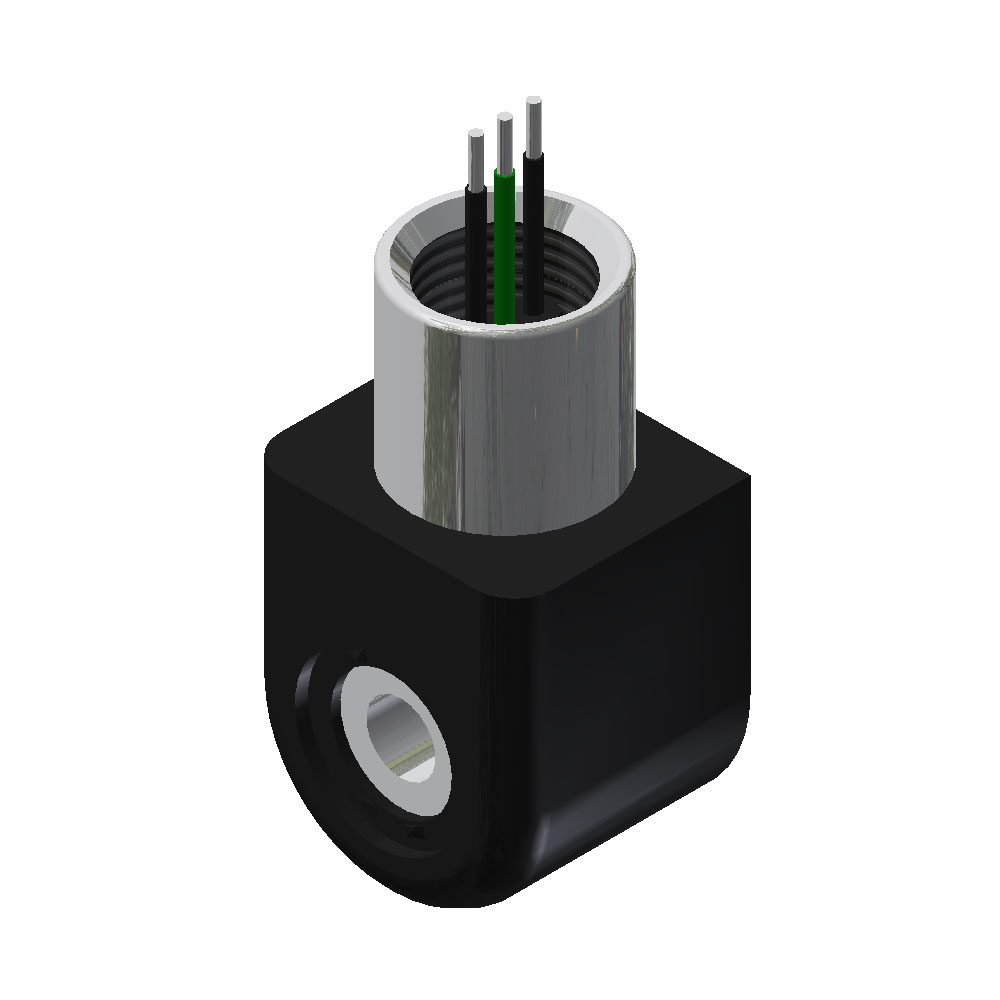

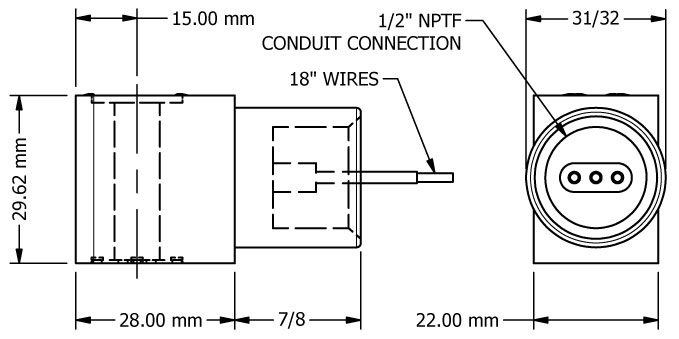

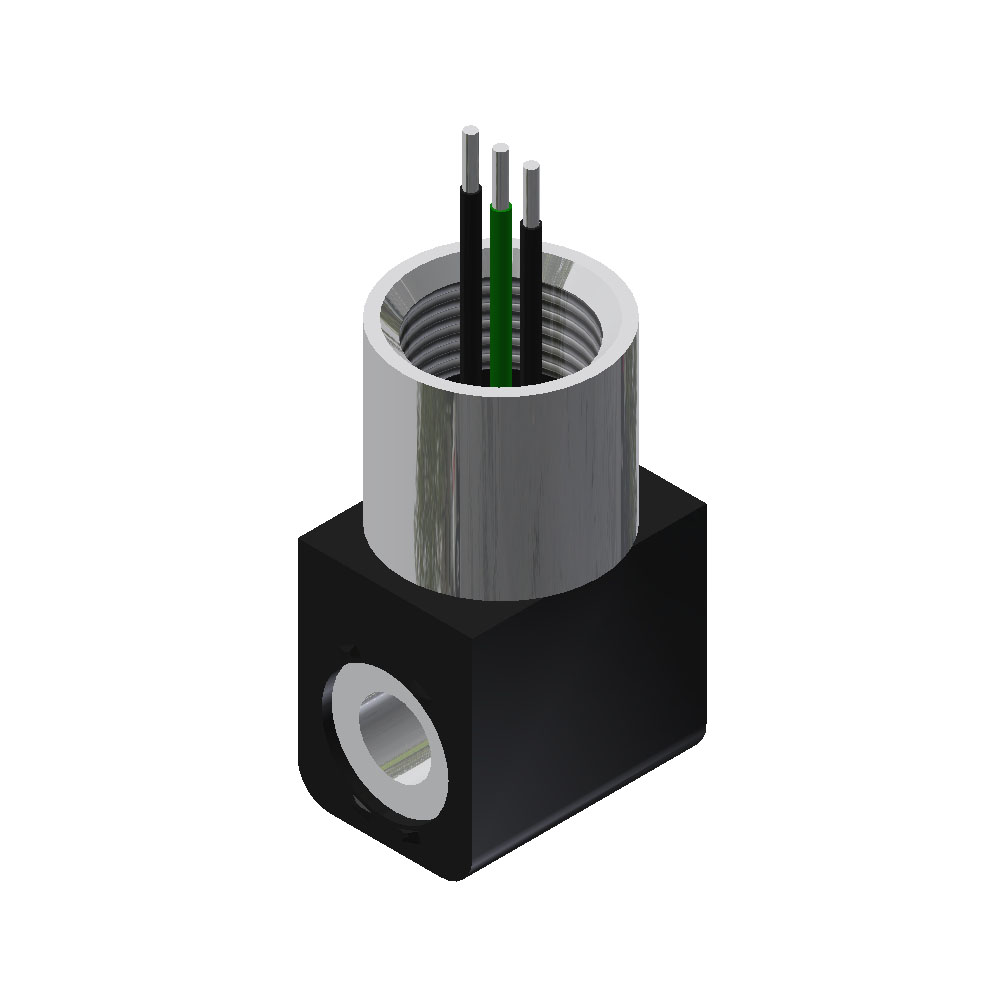

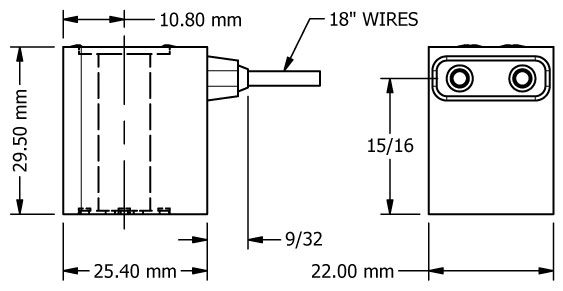

"E-Series" Coil - Option J - 1/2" Conduit Mold-Over

The mold-over coil has a 1/2" NPT conduit connection with three 18" long wires. The coil is 22mm wide. Coil can be rotated in 90° increments on operator stem when space is available. When connecting to an electrical source either black wire can be connected to hot (+) and the other connected to neutral (-). The green wire is the ground (earth).

| Voltage | Pick-Up | Holding | Resistance | Spare Coil | |

|---|---|---|---|---|---|

| 24 volts, 60 Hz | 7.1 VA | 5.8 VA | 31.6 ohms |   | |

| 48 volts, 60 Hz | 7.7 VA | 6.2 VA | 121 ohms | ||

| 120 volts, 60 Hz | 7.8 VA | 6.3 VA | 820 ohms | ||

| 240 volts, 60 Hz | 7.8 VA | 6.3 VA | 3400 ohms | ||

| 12 volts D-C | 4.6 Watts | 31.6 ohms | |||

| 24 volts D-C | 4.8 Watts | 121 ohms | |||

| 60 volts D-C | 4.3 Watts | 820 ohms |

Ambient Temperature: -20°C to +80°C.

Relative Duty Cycle: 100%.

Degree of Protection: IP65.

Voltage Tolerance: ± 10%.

Resistance Tolerance: ± 8% at 20°C.

Insulation Class: F

"E-Series" Coil - Option M - 18" Flying Lead

The flying lead coil has two 18" long wires. The coil is 22mm wide. Coil can be rotated in 90° increments on operator stem when space is available. When connecting to an electrical source either black wire can be connected to hot (+) and the other connected to neutral (-).

| Voltage | Pick-Up | Holding | Resistance | Spare Coil | |

|---|---|---|---|---|---|

| 24 volts, 60 Hz | 7.1 VA | 5.8 VA | 27.4 ohms |   | |

| 48 volts, 60 Hz | 7.7 VA | 6.2 VA | 97.9 ohms | ||

| 120 volts, 60 Hz | 7.8 VA | 6.3 VA | 619 ohms | ||

| 240 volts, 60 Hz | 7.8 VA | 6.3 VA | 3400 ohms | ||

| 12 volts D-C | 4.6 Watts | 27.4 ohms | |||

| 24 volts D-C | 4.8 Watts | 97.9 ohms | |||

| 60 volts D-C | 4.3 Watts | 619 ohms |

Ambient Temperature: -20°C to +50°C.

Relative Duty Cycle: 100%.

Degree of Protection: IP65.

Certifications: This coil carries the UL certificate of compliance both the standard and Canadian certification. A copy of the certification is available here. The rating only applies to the coil and not the entire valve.

Voltage Tolerance: ± 10%.

Resistance Tolerance: ± 8% at 20°C.

Insulation Class: F

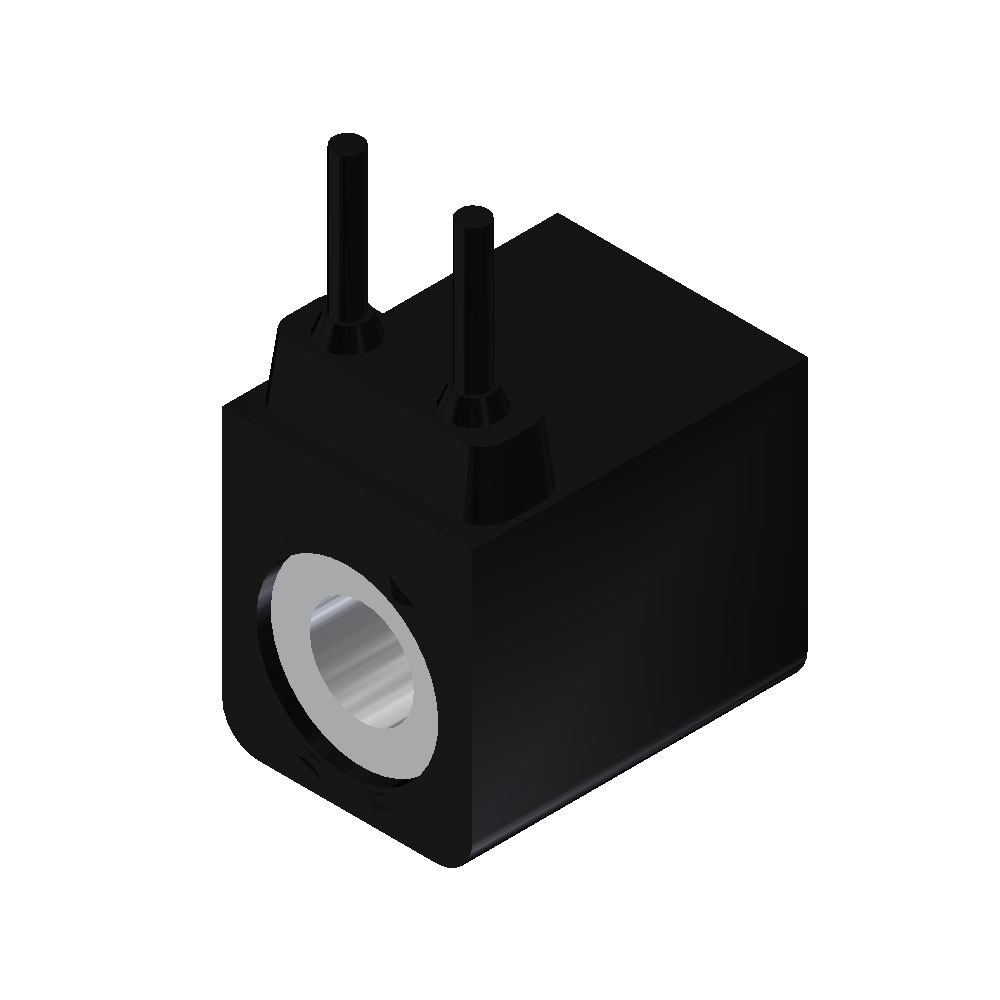

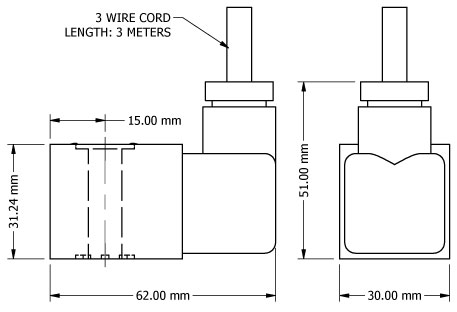

"E-Series" Coil - Option T - ATEX

The ATEX/IEC coil is molded with 3 meters of 3 wire cord. The wire has one green/yellow ground (earth) wire, one brown wire and one blue wire. Either the brown or blue wire can be hot (+) and the other neutral (-). The coil is 30mm wide. These coils are rated by the European standards PTB 03 ATEX 2018 X, IECEx PTB 04.0002X. See below for exact approvals. Coil can be rotated in 45° increments on operator stem when space is available.

| Voltage | Pick-Up | Holding | Resistance | Spare Coil |

|---|---|---|---|---|

| 24 volts D-C | 0.136 amps | 177 ohms |

Ambient Temperature: -20°C to +50°C.

Relative Duty Cycle: 100%.

Degree of Protection: IP65 (IP67 possible with accessories).

Certifications: This coil carries the ATEX/IEC certificate of conformity. A copy of the certification is available here. The rating only applies to the coil and not the entire valve.

Voltage Tolerance: ± 10%.

Resistance Tolerance: ± 8% at 20°C.

Insulation Class: H

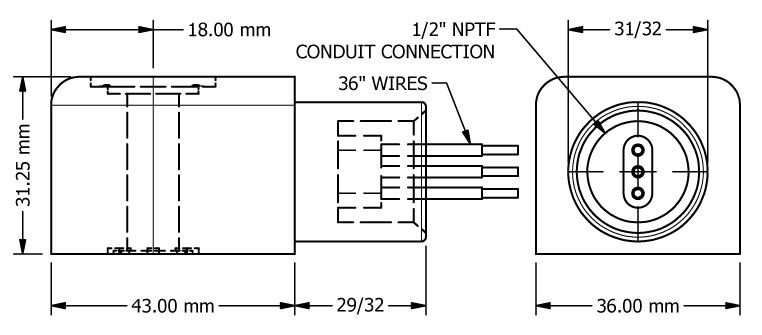

"E-Series" Coil - Option X - Explosion Proof

The explosion proof coils are a 1/2" NPT conduit connection with one green ground wire and two black wires. When connecting to an electrical source either black wire can be connected to hot (+) and the other connected to neutral (-). The green wire is the ground (earth). The coil is 36mm wide. On some valves this may interfere with mounting and a spacer may be used under the valve. These coils are rated explosion proof for Class I, Division 1, Groups A, B, C and D (gasoline vapors, etc.), Class II, Groups E, F, and G (coal, coke and grain dusts), Class III. See below for exact approvals. Other voltages not shown below are available. Coil can be rotated in 90° increments on operator stem when space is available.

| Voltage | Pick-Up | Holding | Resistance | Spare Coil |

|---|---|---|---|---|

| 120 volts, 60 Hz | 6.8 VA | 530 ohms | ||

| 12 volts D-C | 4.5 Watts | 31.6 ohms | ||

| 24 volts D-C | 4.6 Watts | 121 ohms | ||

| 240 volts, 60 Hz | 6.8 VA | 2345 ohms | V-593-4 |

Conduit Material: on V-593-1 thru -3, stainless steel. On V-593-4, zinc plated.

Ambient Temperature: -20°C to +60°C.

Relative Duty Cycle: 100%.

Degree of Protection: IP65 with connector (IP67 possible with accessories).

Certifications: This coil carries both a FM and CSA approval rating; CSA CLASS 2258 02, process control equipment for hazardous locations; FM CLASS 3600, 3611, 3615, 3810, hazardous (classified) location electrical equipment. A copy of the certification is available here. The rating only applies to the coil and not the entire valve.

Voltage Tolerance: ± 10%.

Resistance Tolerance: ± 8% at 20°C.

Insulation Class: H

Commonly Asked Questions

Q: Can I use a piece of equipment approved for use in a Division 1 hazardous location in a Division 2 hazardous location?

A: Yes. If equipment has been approved for use in a Division 1 hazardous location, it can be used in a Division 2 hazardous location, providing it is in the same class and group.

A: Yes. If equipment has been approved for use in a Division 1 hazardous location, it can be used in a Division 2 hazardous location, providing it is in the same class and group.

Q: Can equipment approved for a Class I hazardous location be used in a Class II hazardous location?

A: No. Equipment used in Class I and Class II hazardous locations are made for different purposes. Equipment approved for Class I hazardous locations must contain an internal explosion, while Class II approved equipment must seal out dust. They are not interchangeable.

A: No. Equipment used in Class I and Class II hazardous locations are made for different purposes. Equipment approved for Class I hazardous locations must contain an internal explosion, while Class II approved equipment must seal out dust. They are not interchangeable.