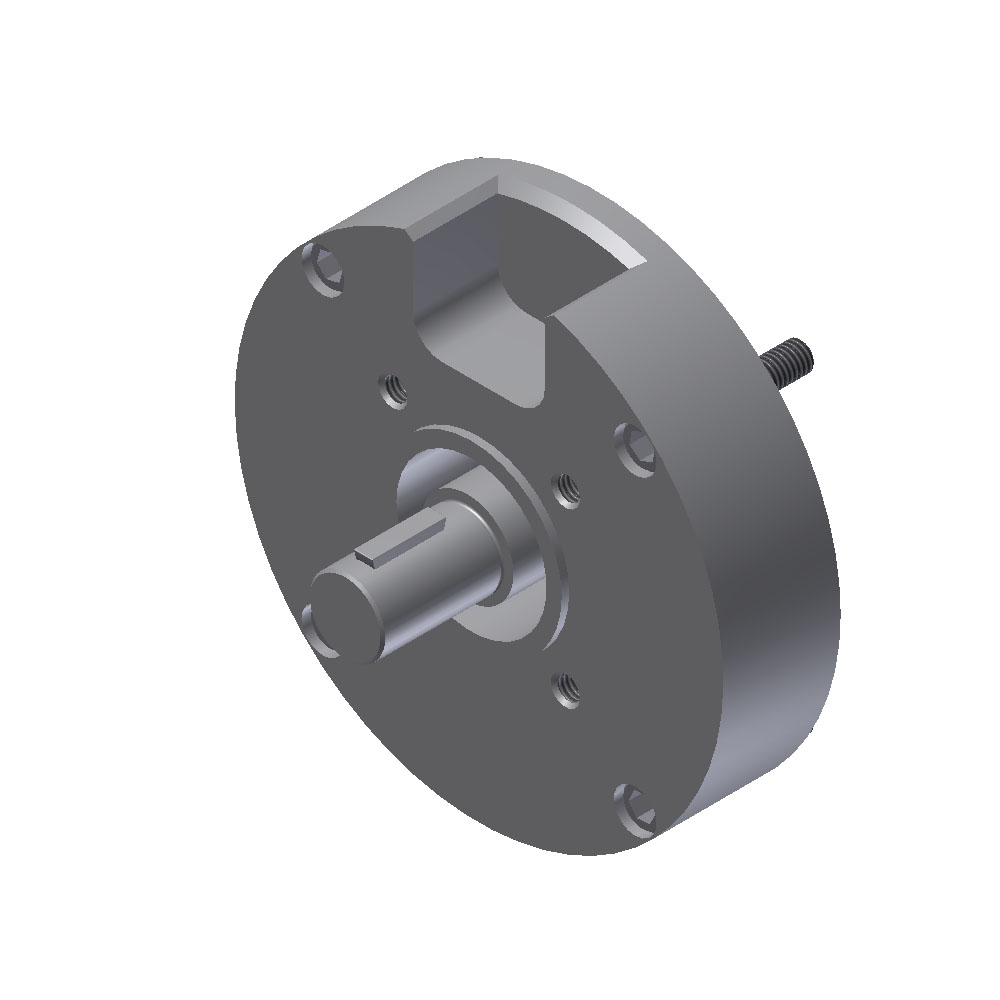

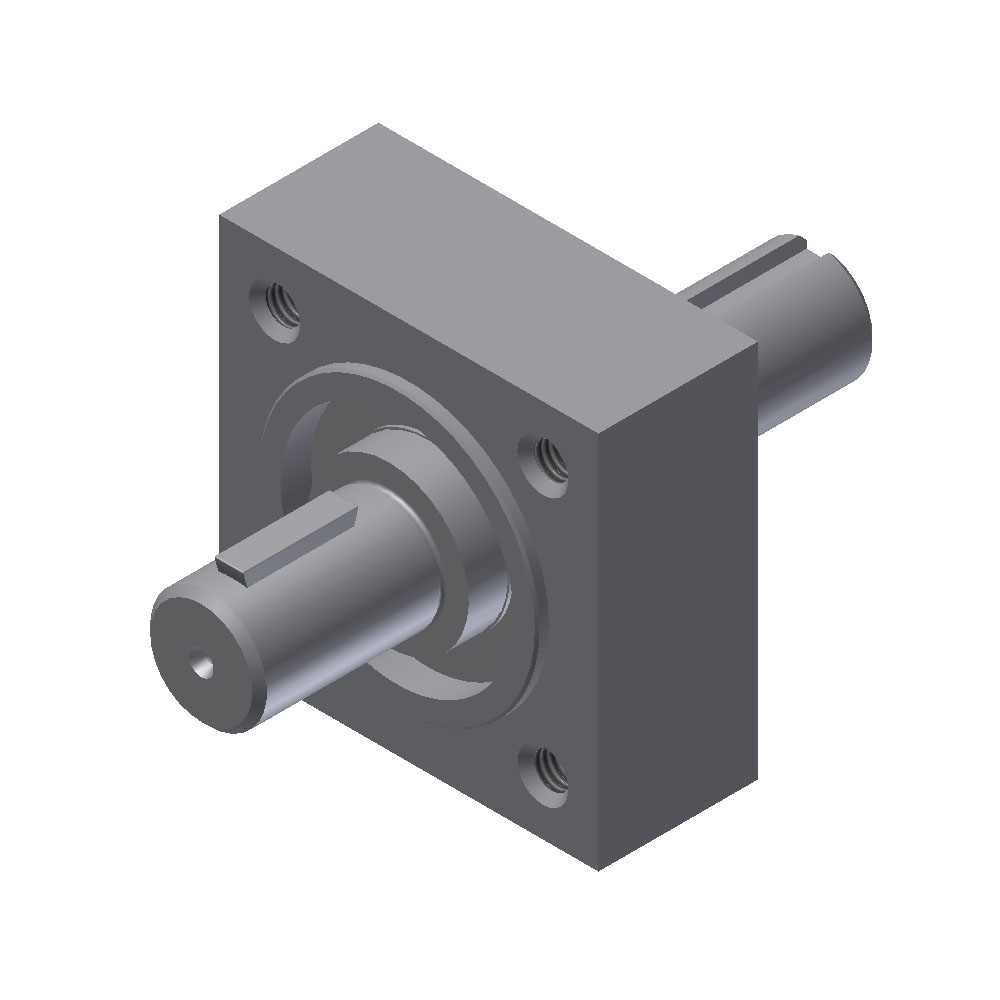

Available Drive Styles for Jiffy-Drill

The Jiffy-Drill can be ordered with choice of 20 hydraulic motor models covering a wide range of speed/torque ratios. Motor selection depends on the drill bit diameter, speed, and the hardness of the material to be drilled. Hydraulic motors can be attached in any 90º increment for easy plumbing. All Jiffy motors are reversible.

There is a choice of 8 motor models for medium speed tapping up to 2200 RPM. A choice of another 12 motor models for low speed, high torque tapping with larger taps or when working with harder materials. Consult factory for additional high speed, low torque motors for applications up to 5000 RPM.

Motors A-1 through A-4 and M-0 through M-3 are for high speed drilling up to 2200 RPM. Motors B-0 through B-8 are low speed, high torque motors for larger bits or harder materials.

In order to size the proper hydraulic motor, you must know what RPM and torque is required for the cutting tool to machine the material you are using. This information can usually be obtained from the manufacturer of the cutting tool used. For standard twist drills, see pages 19 through 22 to estimate required torque, RPM and thrust. Then refer to pages 53 through 57 to choose a hydraulic motor that will deliver the torque and RPM needed. If you will be using an existing power unit, you will be limited by the pressure and GPM available from your existing power unit. On new applications try to keep operating pressures around 600 - 800 PSI and GPM at 25% to 75% of maximum GPM the motor can operate at.