Compressed Air, Gas & Vacuum Valves

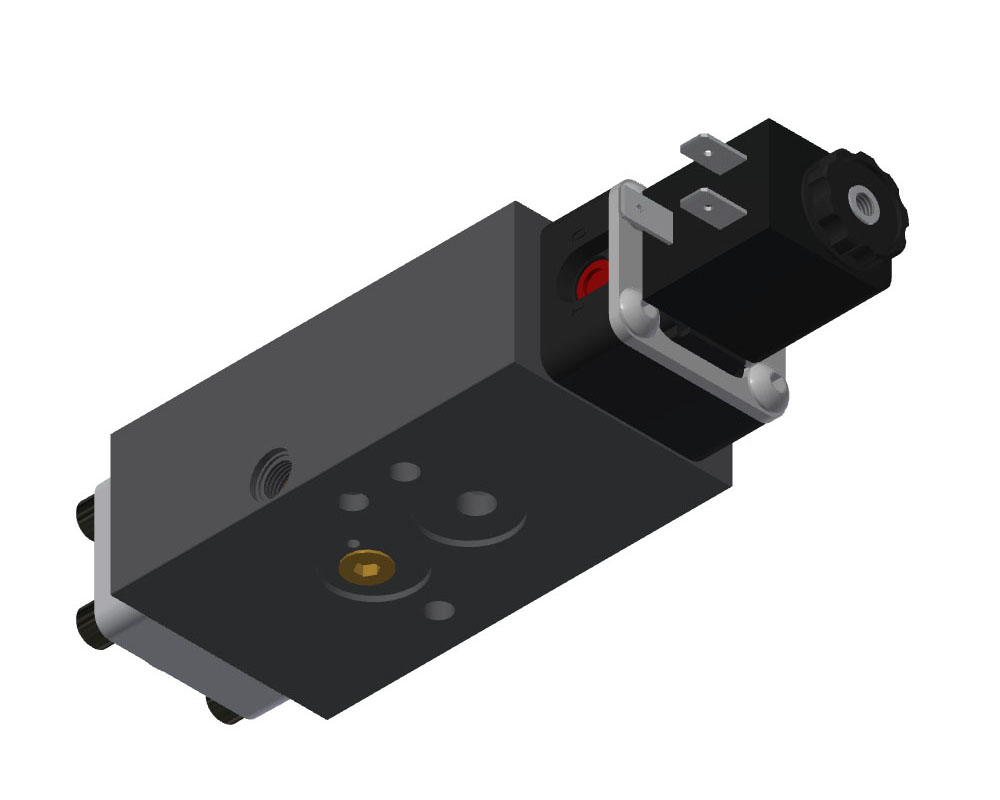

AAA Products International offers one of the most versatile lines of directional control air valves in

the industry, with a wide range of sizes and types. AAA valves are economically priced and built to last

through millions of trouble free cycles.

AAA (pronounced Triple A) valves are precision manufactured to close tolerances on computerized

numerically controlled machines and specially designed custom equipment using the highest quality

materials. AAA valves are designed to use compressed air or gas at pressures from vacuum to 250 PSI.

Side and bottom ported valves are sized from 1/4" to 2" NPTF. Stack valves are available in 1/4" and

3/8" NPTF sizes.

In addition to the wide range of standard valves, AAA manufactures over 500 special

valves with options such as high pressure, special actuators, spool type variations, stainless

steel, brass, Tufram® coated.

AAA Valves have proven superior performance under the toughest conditions. We

invite you to try them on your toughest jobs. We know you will be pleased.

General Information on AAA Valves

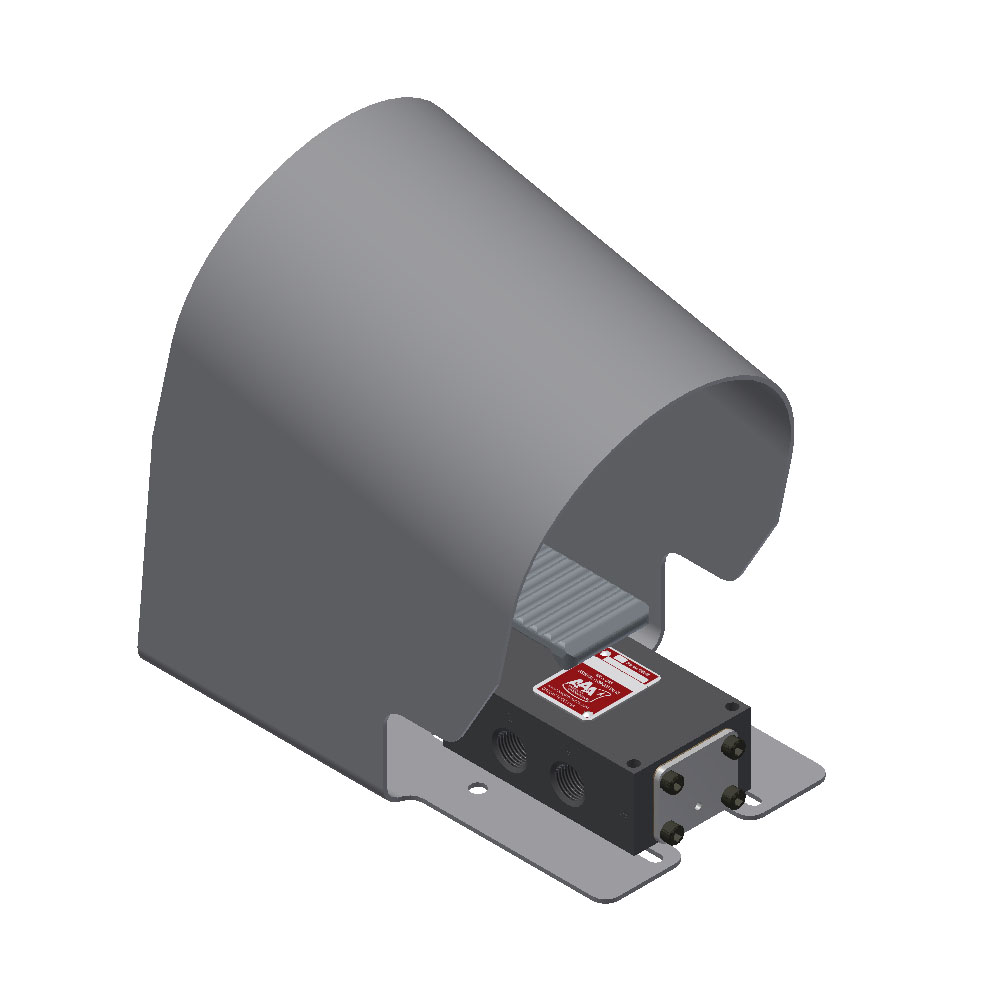

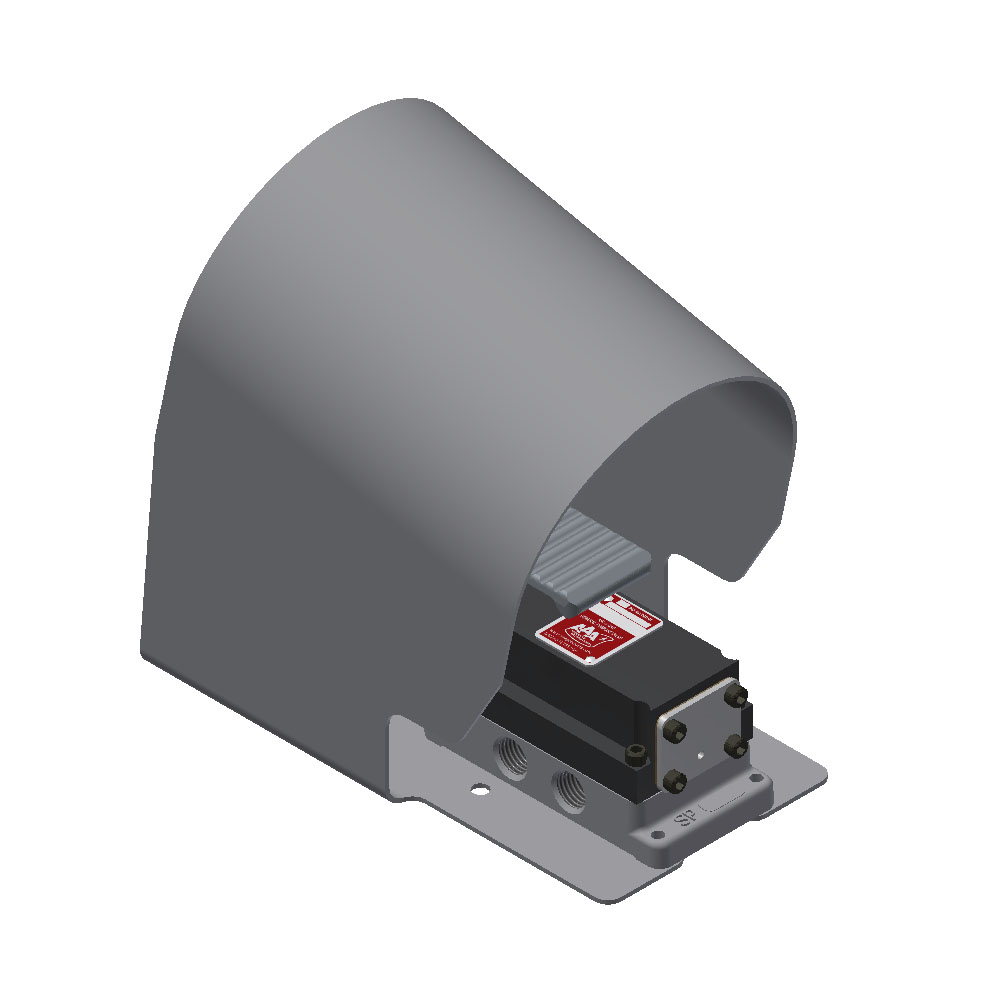

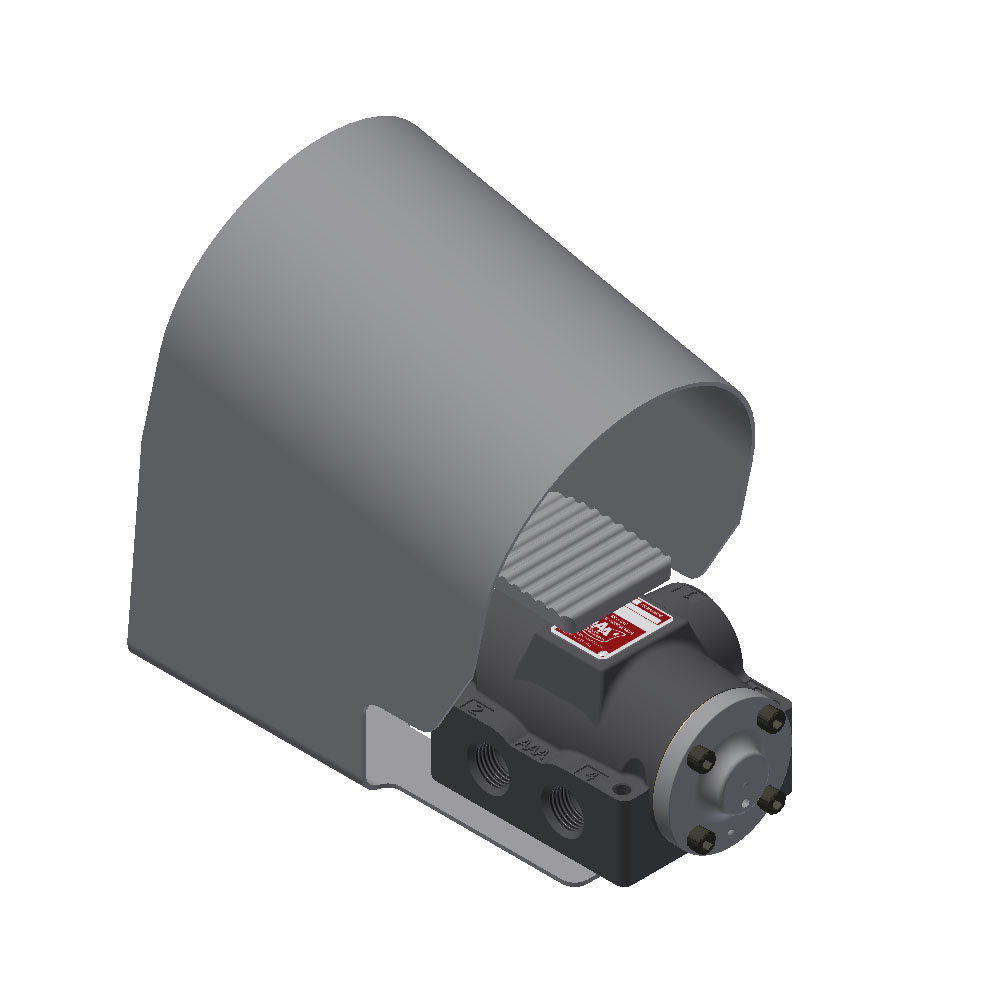

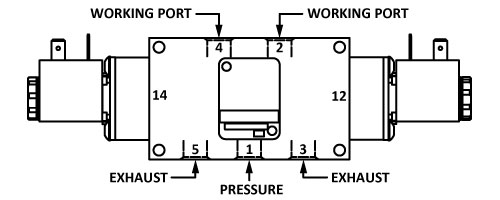

AAA valves are spool-type with 4-way action and are intended primarily for control of air cylinders or air motors. Soft seal models, which include all listings, are for air, inert gas or low vacuum service up to 28" Hg. They are offered in a complete size range from 1/4" to 2". O-Rings give tight sealing between all ports.

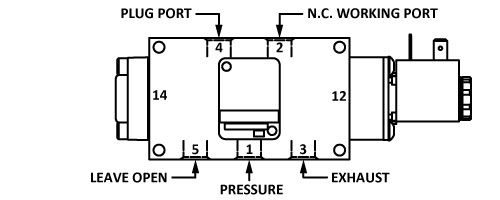

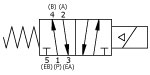

4-Way Action

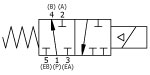

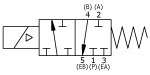

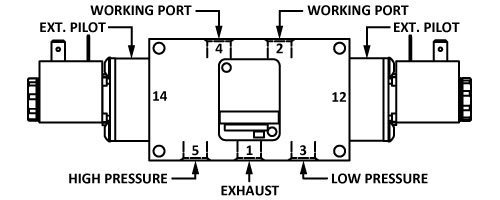

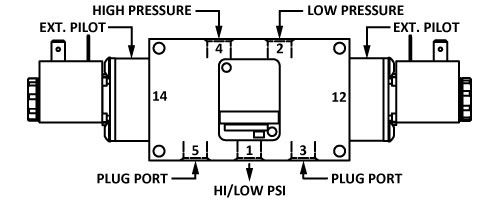

AAA valves have 4-way

spools for control of reversible cylinders and similar devices. Soft seal models can be used as 3-way valves by

plugging the unused cylinder port, or as 5-way valves by using the dual

exhaust ports as inlets and the inlet port as a single exhaust.

Side Ported Body Sizes

Soft seal valves are built in 4 side ported body sizes. The 1/4" and 3/8" valves are housed in the

smallest body. Both are identical except for a slight difference in flow capacity. The 1/2" valves are

in the next larger body. The 3/4" and 1" valves are in a still larger body. They are identical in

appearance but have a slightly different flow capacity. The largest body is used for 1-1/2" and 2"

valves. These two sizes are the same except for NPTF body ports on the 1-1/2" models and 2" subplate

ports on the 2" models.

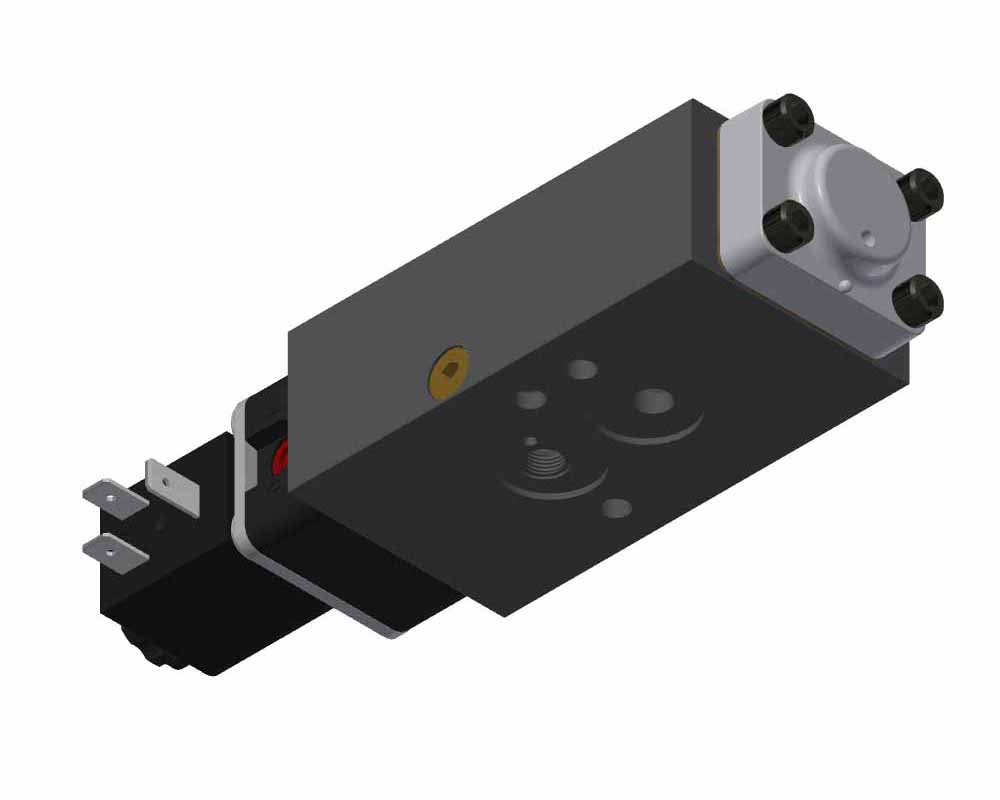

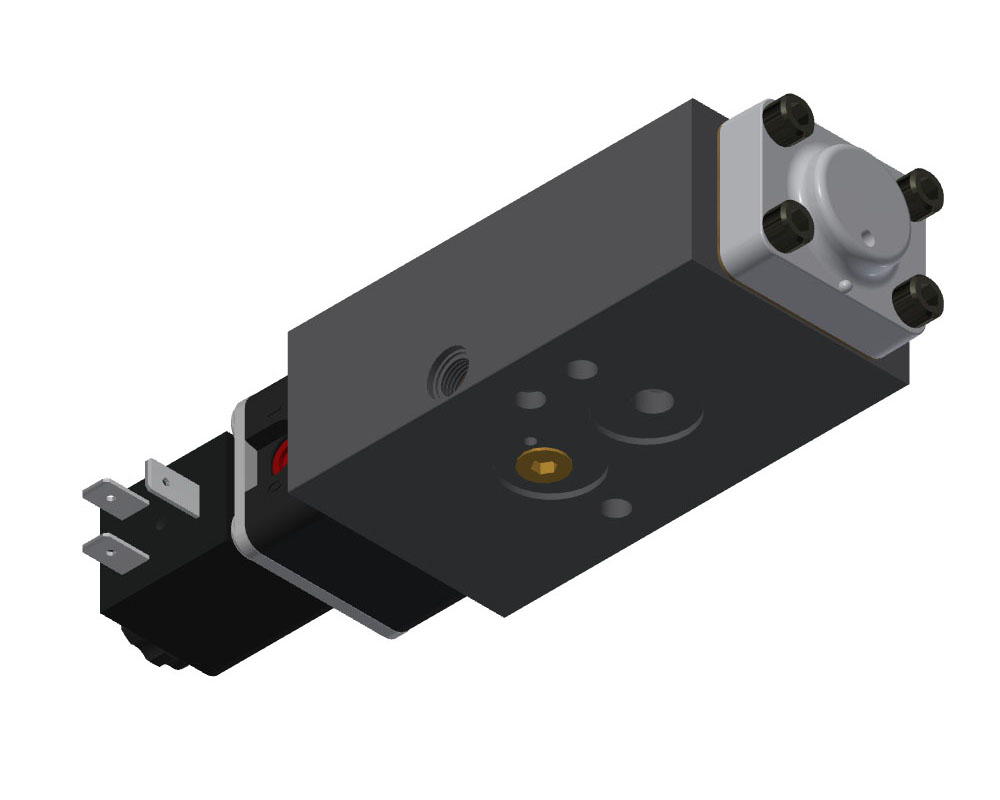

Models for Subplate Mounting

Subplate mounting is offered in all body sizes except "NAMUR" and "B-Series" stack valves. 1/4" and 3/8"

valves have flow area equal to 5/16" orifice and can mount on a subplate with 1/4" or 3/8" connections.

1/2" valves have a flow area of 1/2" orifice and can mount on subplates with 1/2" connections. 3/4" and

1" valves have a flow area of 3/4" orifice and can mount on subplates with 3/4" or 1" connections.

1-1/2" and 2" valves have a flow area of 1-3/8" orifice and can mount on subplates with

1-1/2" or 2" connections.

Mounting of Valves

AAA valves may generally be mounted in any position. But for safety, any valve which does not have

springs or detents to hold the spool in position should be mounted with the spool horizontal unless

pressure is continually applied to hold the spool in position.

Pressure Ratings

On air service, valves will tolerate surge pressures to 1000 psi without permanent damage to bodies or

seals, but for safety and reliable operation they should not be used above rated 250 psi pressure.

Solenoid valves are limited to 150 psi unless converted to external piloting. Button bleeder models will

not operate on vacuum nor on line pressure less than 25 psi (50 psi on spring models).

Materials of Construction Bodies of 1/4" and 3/8" sizes are solid aluminum. Larger bodies are heat treated aluminum castings. Spools are machined from light-weight aluminum alloy bar stock, and specially treated to produce a glass-hard surface finish. End caps are steel or aluminum. Viton O-rings are standard on 1/4" and 3/8" bodies; Buna-N O-rings are standard on larger bodies. O-rings are installed in body grooves, not around the spool.

Factory Prelubrication

All valves are pre-lubricated at the factory using Magnalube-G teflon based all purpose grease. Valves

are suitable for

and perform best in a low lube service.

For long life, use an air line filter/lubricator installed no further than 8 to 10 feet from the valve.

The filter should be rated 25 pm or finer. Use a high grade of petroleum base non-detergent lubricating

oil no heavier than SAE lOW. DO NOT OVER-LUBRICATE. This could cause the spool to stick. You should not

see oil dripping or misting through the exhaust ports of the valve.

CAUTION! Do not use questionable fluids in air line lubricators. Do not use petroleum oil with detergent

additives, volatile or aromatic fluids, vegetable oil, cup grease, or automobile chassis lubricant. The

use of questionable fluids may swell rubber seals in valves and cylinders.

Recommended Lubrication

When cleaning AAA valves after extended service, lubricate the valve spool with AAA high film strength

grease, or use O-ring grease which is usually available from supply houses which sell O-rings.

Magnalube-G is included in all valve repair kits for proper valve maintenance.

AAA Products International recommends the use of Magnalube-G in all of its products. This teflon based

lubricant is rated to operate under extreme load conditions and wide temperature ranges, mechanically

and chemically stable, water resistant, and reduces the need for repetitive re-applications. We do not

recommend any lubricants that include cleaners or solvents. These types of lubricants have a tendency to

swell the O-rings and reduce the performance of the valve and O-rings must be

replaced.

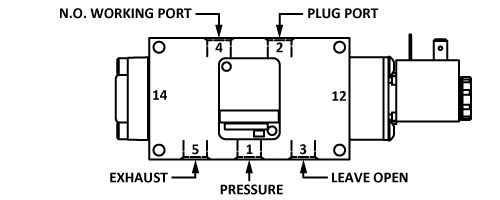

3-WAY N.O. APPLICATION

3-WAY N.O. APPLICATION 3-WAY N.C. APPLICATION

3-WAY N.C. APPLICATION

4-WAY APPLICATION

4-WAY APPLICATION

5-WAY APPLICATIONS

5-WAY APPLICATIONS