7114 Harry Hines Blvd.

Dallas, Texas 75235

214-357-3851

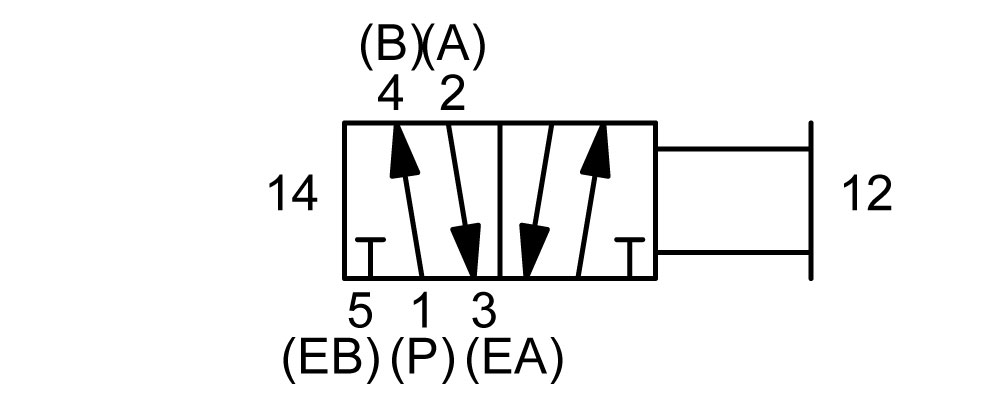

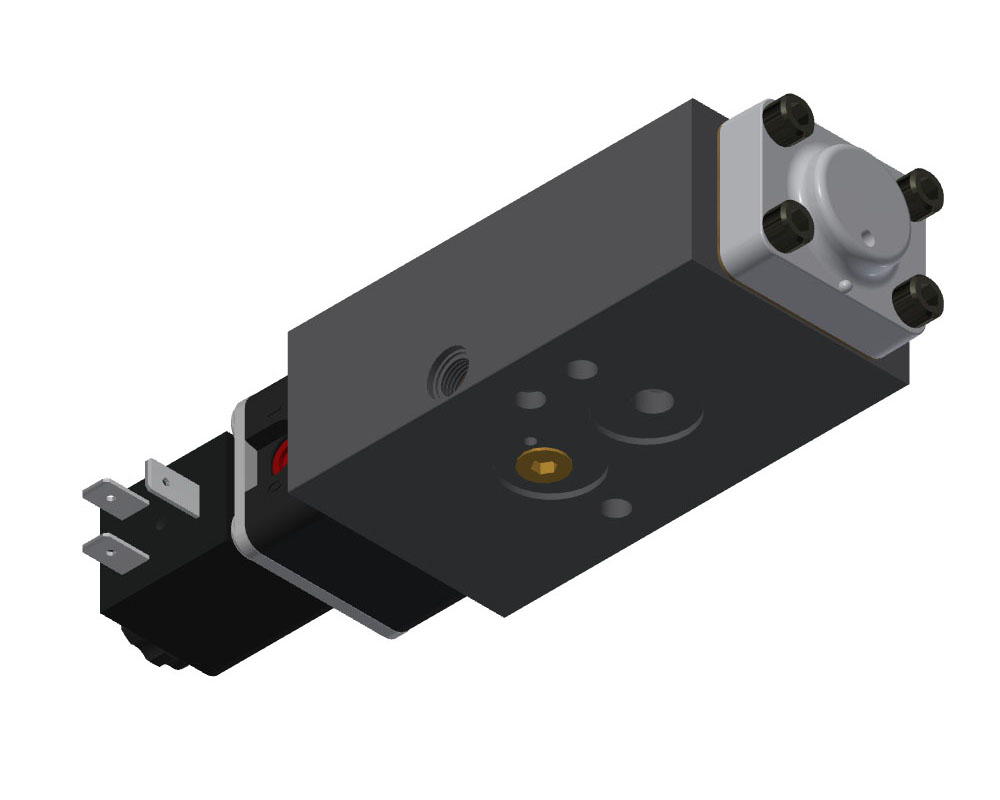

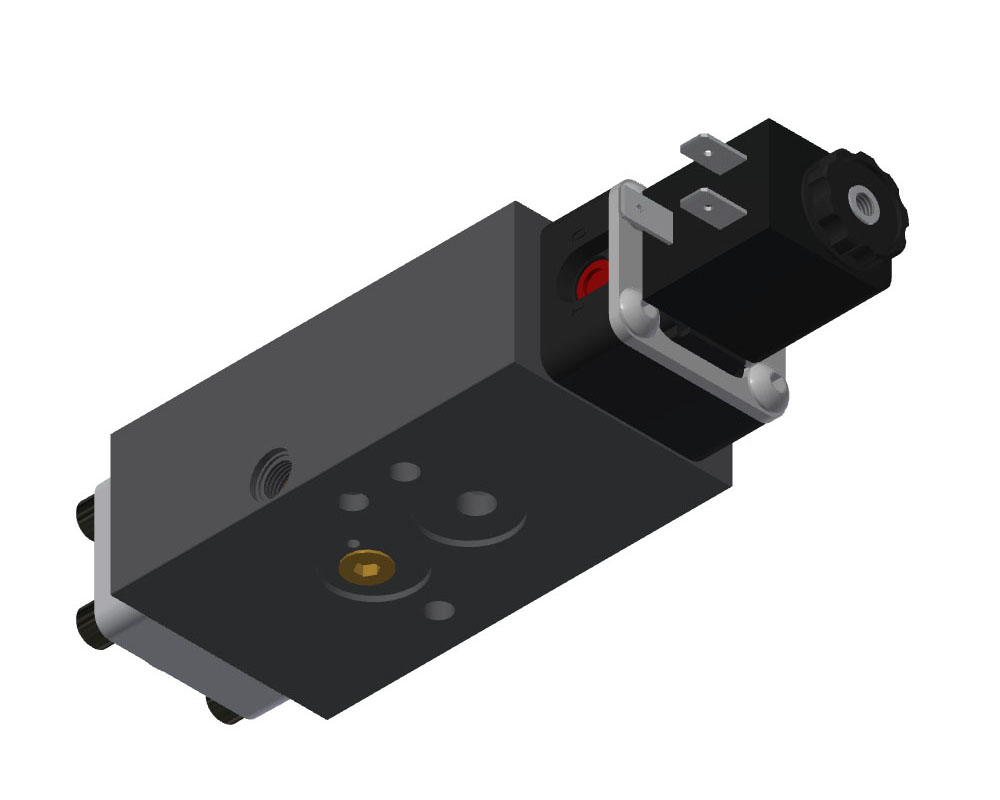

Data for 252V

Details for 252V

Vacuum: The five main ports can be operated on industrial vacuum to 28" Hg, based on a 30" barometer.

Temperature: -20°F to 250°F. Caution: If it is possible that the ambient temperature may fall below freezing, the medium must be moisture free to prevent internal damage or unpredictable behavior.

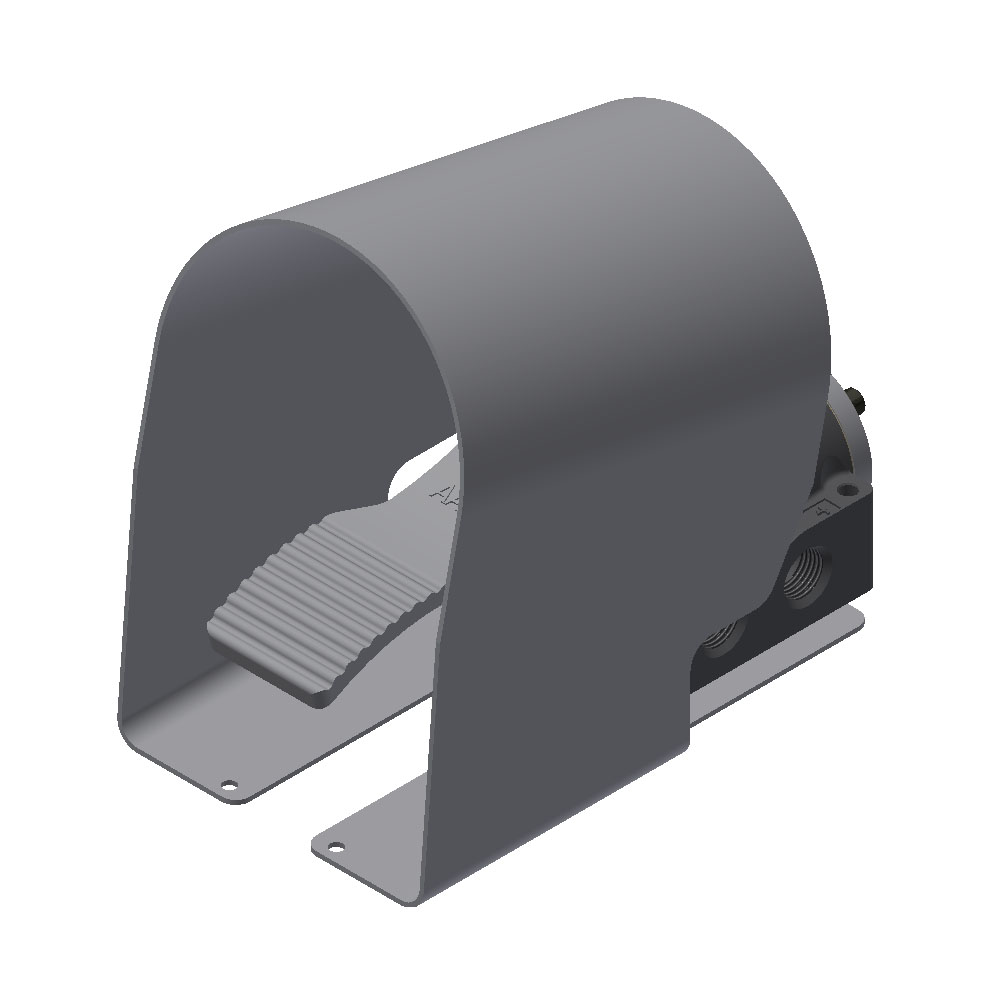

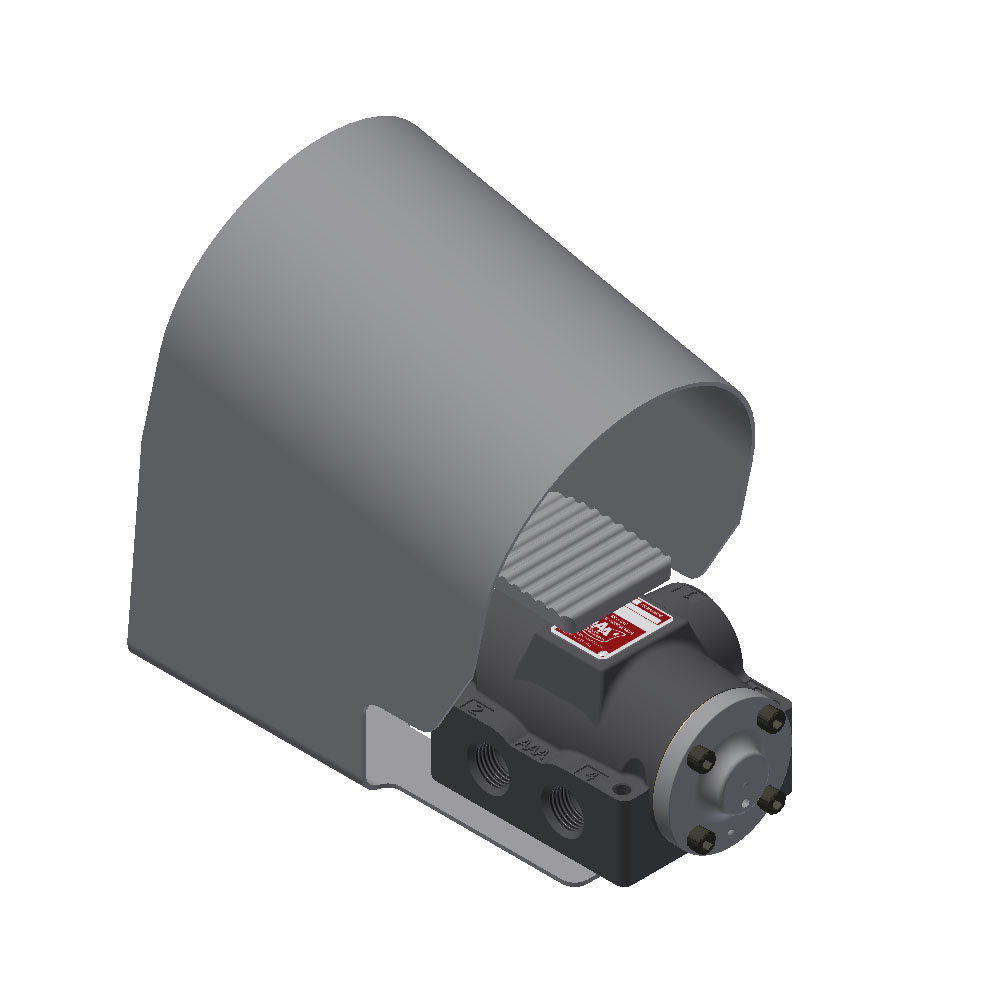

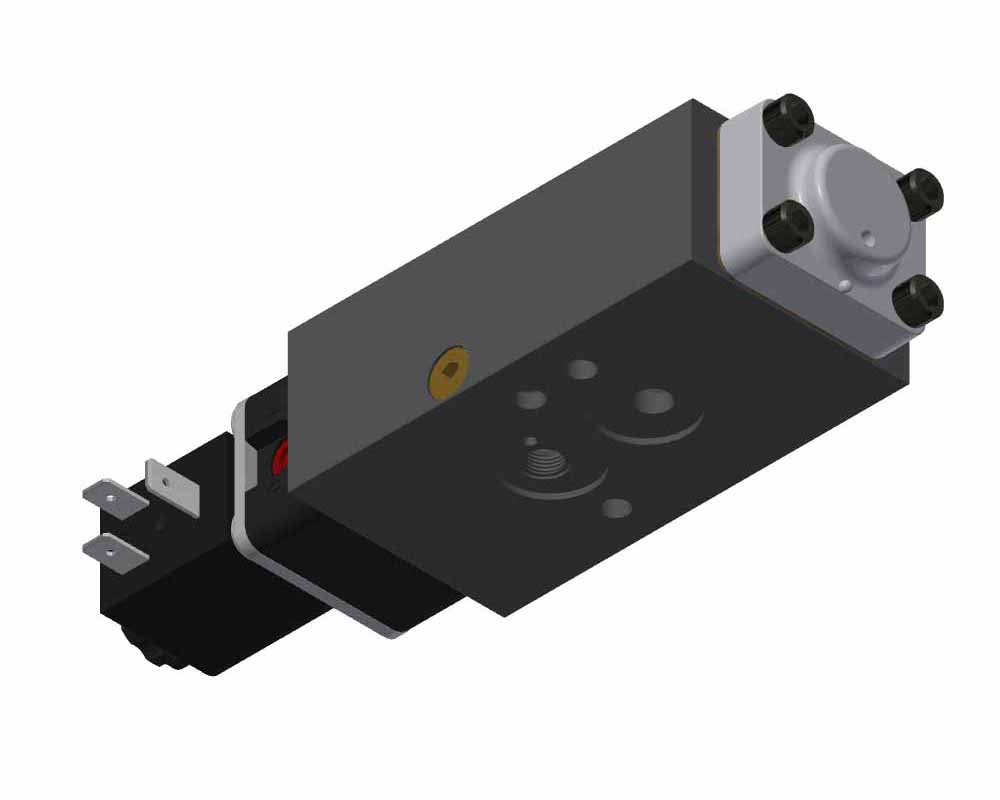

Mounting: The spool is friction positioned so the valve must be mounted with the spool in a horizontal orientation.

O-Rings: Viton.

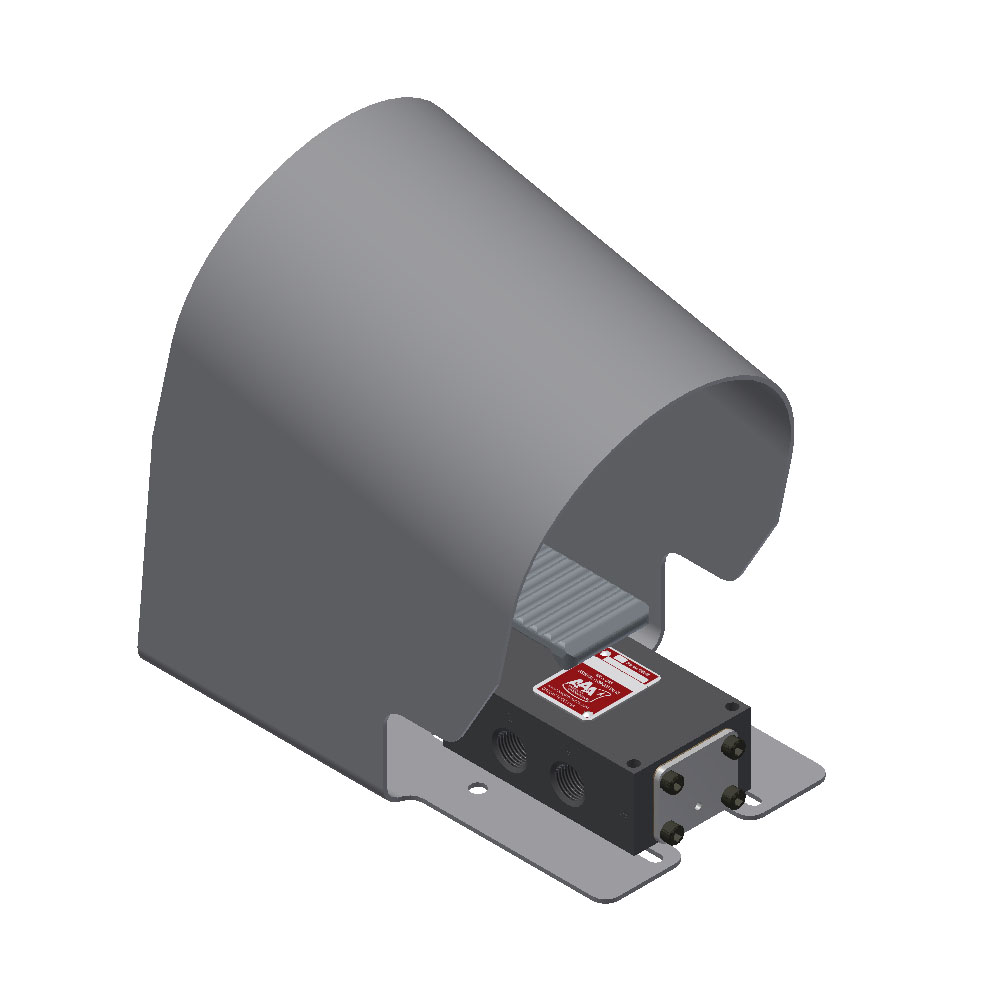

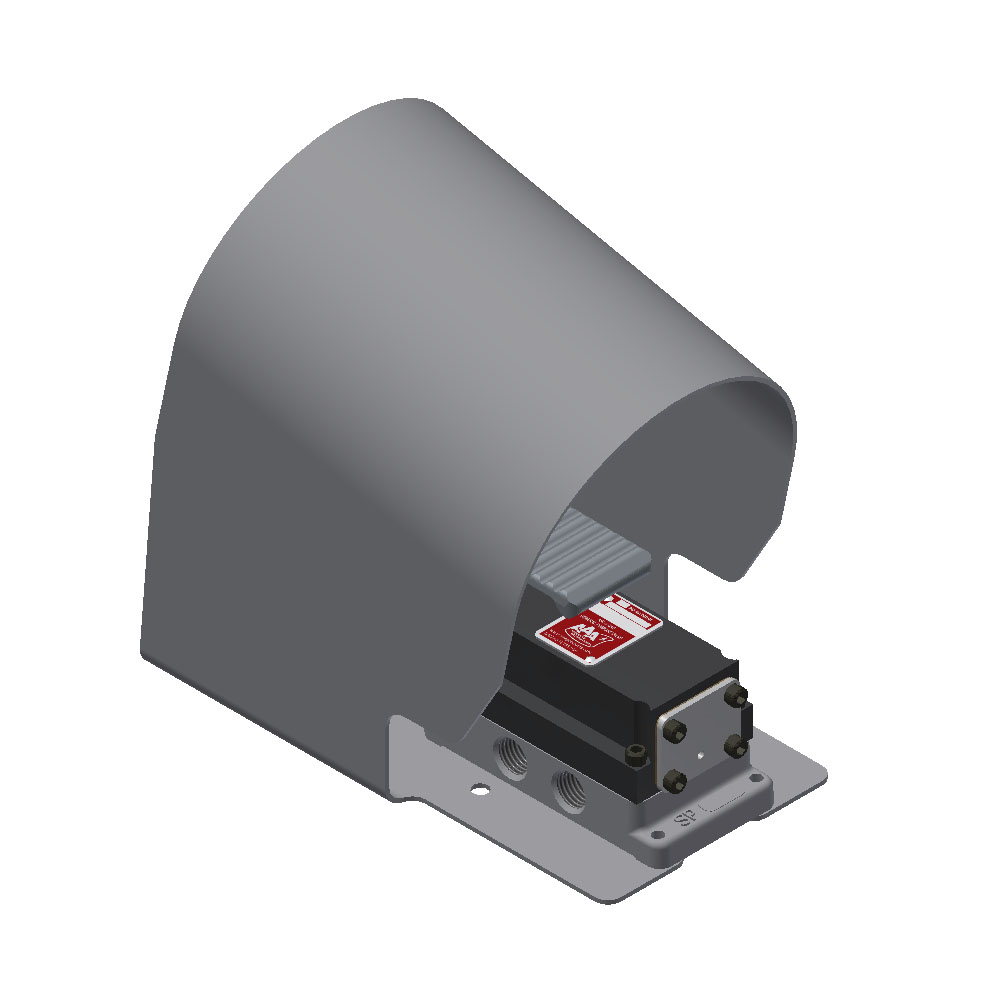

Materials: TUFRAM® coated 6061-T6 aluminum body, hard anodized aluminum spool, A380 aluminum end caps, zinc plated steel stud, composite gaskets, steel fasteners.

Flow: 73.9 SCFM, 1.6 Cv

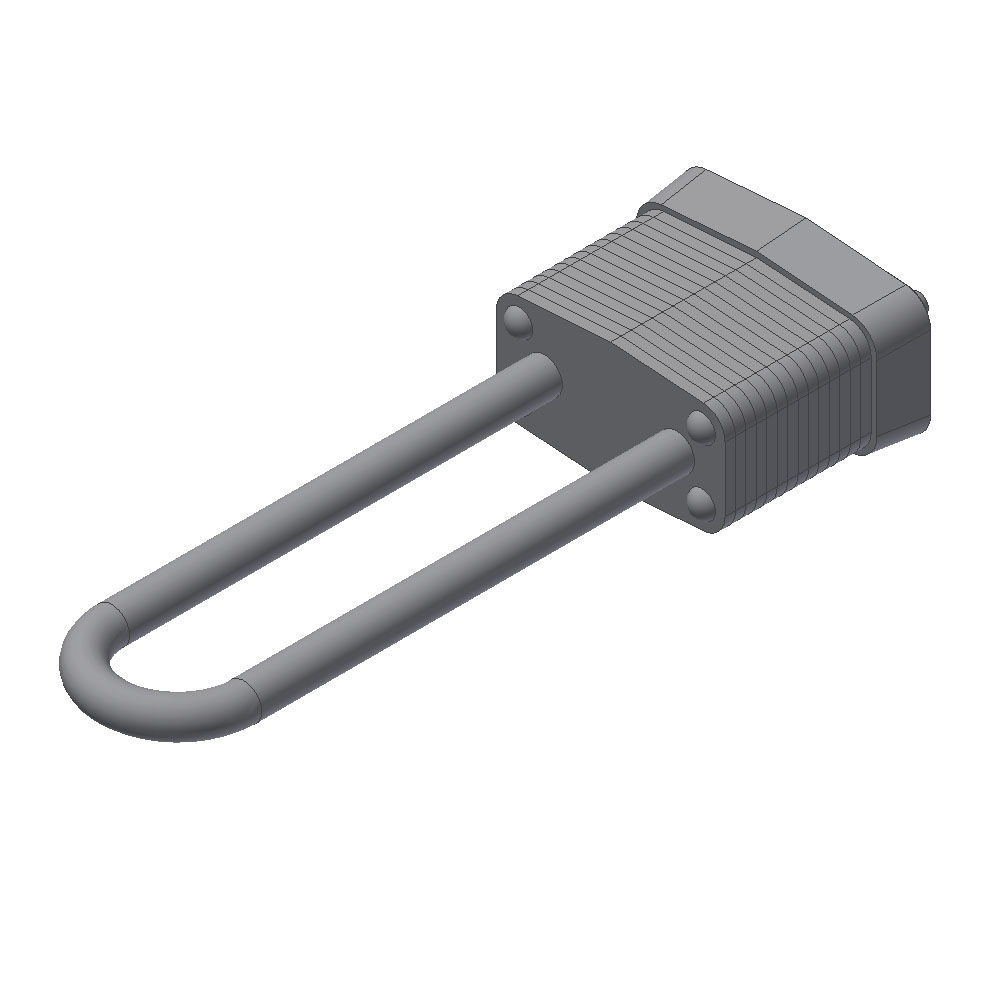

Repair Kit: ERKV-3.

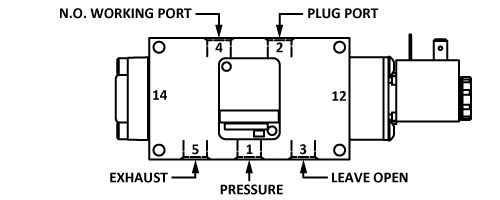

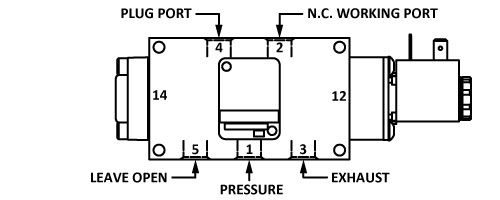

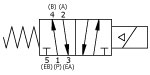

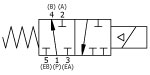

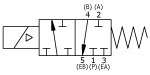

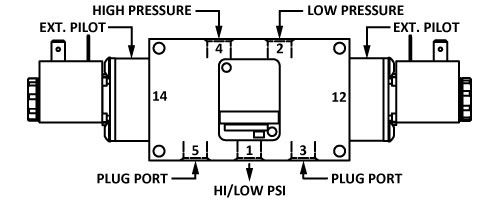

3-Way or 5-Way: While this valve is basically 4-way, it can be used for 5-way service by using ports 2 or 4 as an inlet, or 3-way service by plugging the unused port 2 or 4.

Fluid Media: Soft seal models are made for air, vacuum, and gases compatible with component materials. They should not be used with liquids.

Weight: 1.3 lbs ± 5%.

TUFRAM®

A special surface process called TUFRAM® can be applied to all aluminum and aluminum alloy parts giving them enhanced surface properties. These properties include improved corrosion resistance, abrasion resistance, chemical resistance, moisture resistance, increased hardness, USDA-approved and FDA-approved. This process is ideal for AAA valves that are used in very harsh environments. For example, wash down areas in food processing plants that use caustic solutions for clean-up, off shore oil platforms that are subject to salt water spray, chemical processing plants or valves that must mount outdoors. Please contact us for more information on the use of TUFRAM® L-4 on your application.

Tufram Information

General - Installation & Maintenance

Bulletin A-113: Operating & Maintenance Instructions.

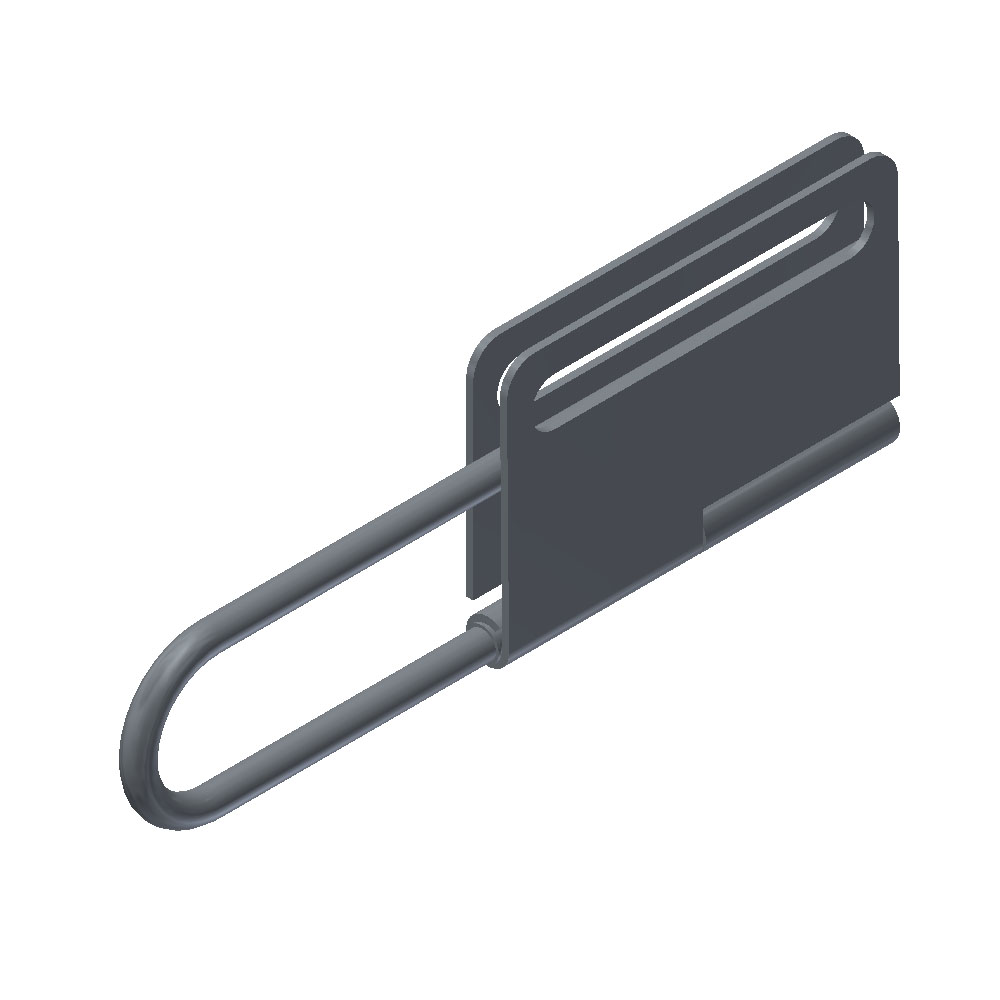

Installation: Valve Fitting Installation.

WARNING:These products can expose you to chemicals which is(are) known to the State of California to cause cancer or reproductive harm. For more information, go to www.P65Warnings.ca.gov. Contact us for specific chemicals or materials used in a product.

WARNING:These products can expose you to chemicals which is(are) known to the State of California to cause cancer or reproductive harm. For more information, go to www.P65Warnings.ca.gov. Contact us for specific chemicals or materials used in a product.

General - Lubrication, Standard

The shelf life of Magnalube-G regularly lasts for 10+ year intervals in closed packaging due to the extremely long operating life of the Elastomer-PTFE gelling agent and premium parafiinic mineral base oil. If the valve is stored for over 2 years, then a small reapplication of grease is suggested.

Magnalube-G Technical Document

Magnalube-G MSDS Document

An alternative grease for low temperature application, refer to Dow-55 grease.

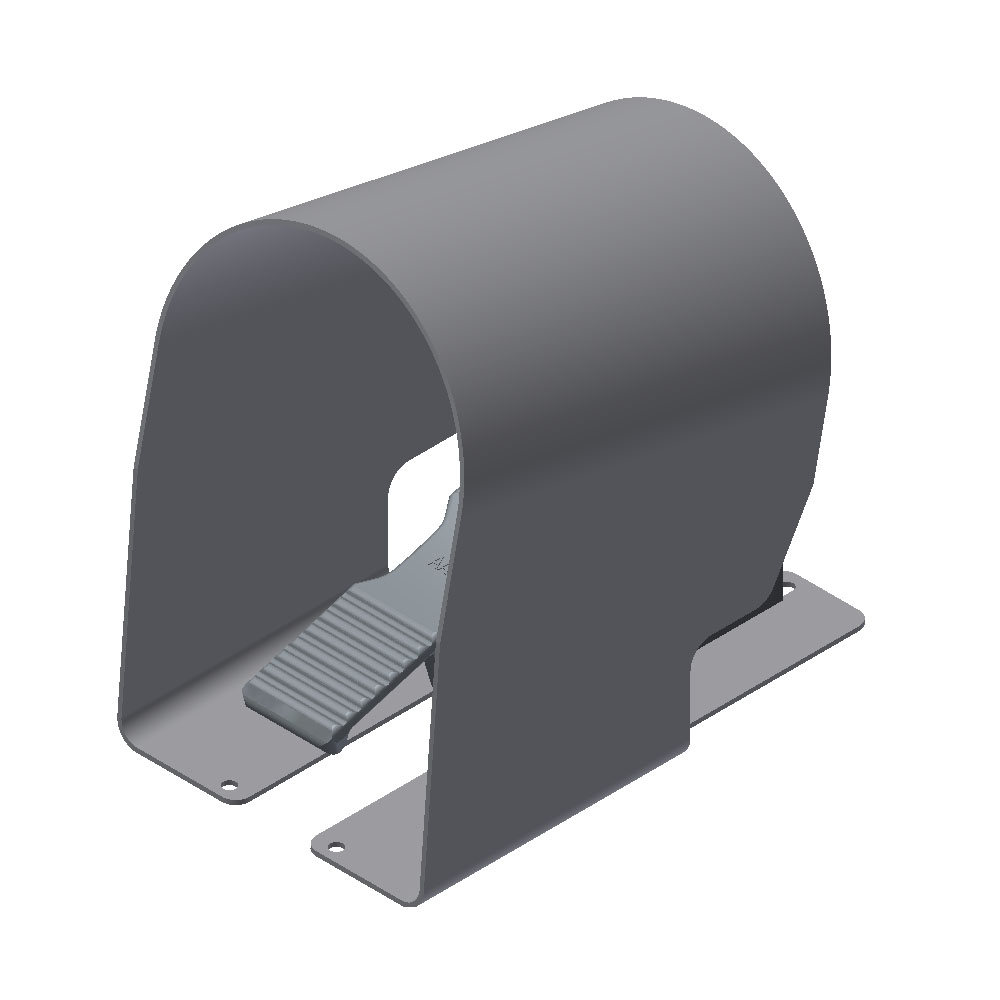

3-WAY N.O. APPLICATION

3-WAY N.O. APPLICATION 3-WAY N.C. APPLICATION

3-WAY N.C. APPLICATION

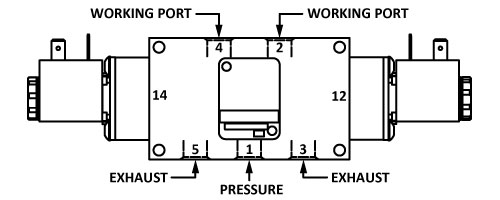

4-WAY APPLICATION

4-WAY APPLICATION

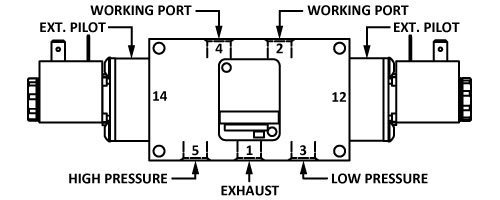

5-WAY APPLICATIONS

5-WAY APPLICATIONS