AAA Products International Inc.

7114 Harry Hines Blvd.

Dallas, Texas 75235

214-357-3851

7114 Harry Hines Blvd.

Dallas, Texas 75235

214-357-3851

General - Solenoid Valve Operation

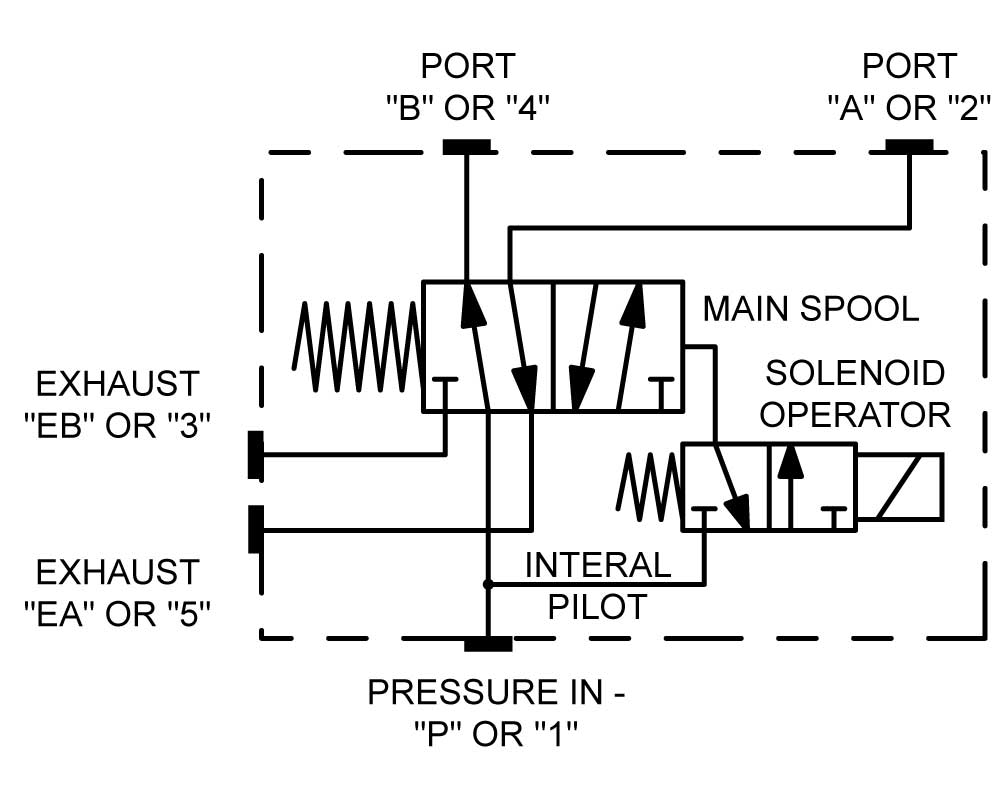

Standard solenoid and "Classic" solenoid operated valves utilize pressure to shift the internal spool which directs the gas flow through ports. The way ports are internally connected depends upon the configuration of the spool and valve connections. The standard configuration for solenoid valve is "Internal Pilot", they can be ordered as "External Pilot" by ording valve with the suffix "Z" or converted in the field. See Bulletin A-113:Operating and Maintenance Instructions shipped with every valve for assistance.

Basic Operation:

When the coil is supplied with the correct power, a magnetic field is generated that pulls in a plunger. The plunger directs the inlet of gas to the end of the internal spool. At the same time, the solenoid exhaust through the stem is blocked, preventing the escape of gas and allowing pressure to build. The increase in the pressure on the end of the spool will shift the spool. Pressure of 25 psi for non-spring models and 50 psi for spring return or spring centered models is required for reliable spool shift (150 psi maximum). When the coil is de-energized, the plunger is returned to position via an internal spring which blocks the inlet of gas to the internal spool. At the same time, the solenoid exhaust is opened and the pressure at the end of the internal spool is allowed to exhaust.

The solenoid can be used as a simple 3-way valve that directs a gas source to the end of the spool or allows the gas from the internal spool to vent. The solenoid vent can be plumbed for direction of exhaust gases.

The return shift of the internal spool is controlled either by a spring, second solenoid, or various mechanical or piloted options.

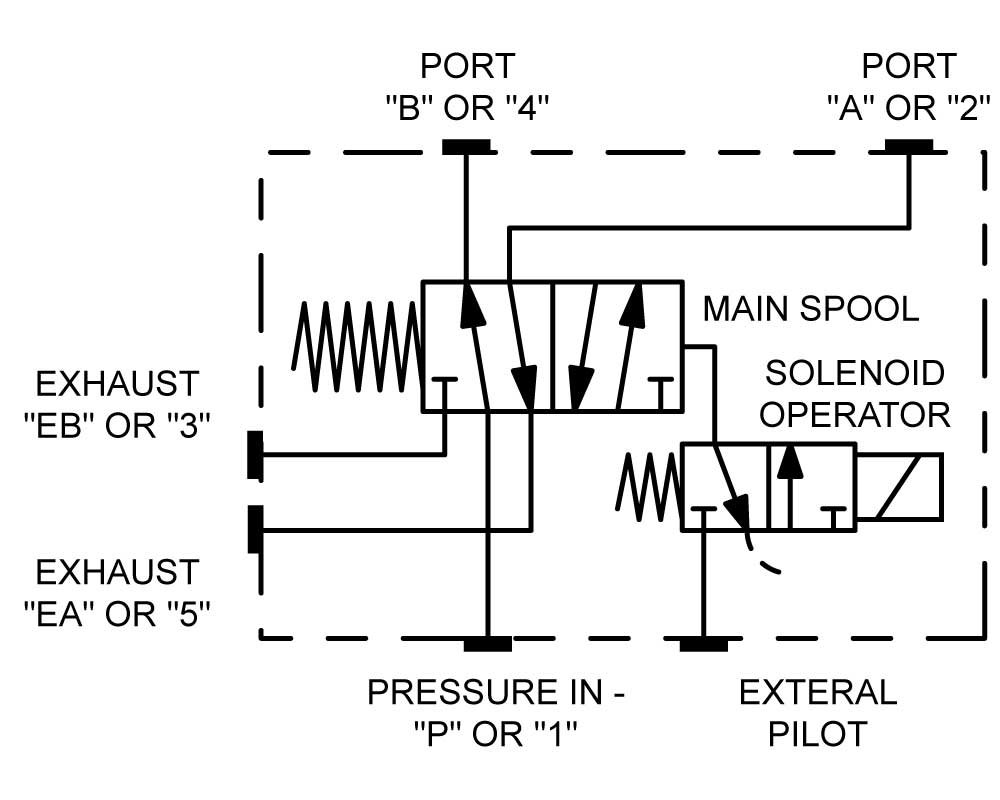

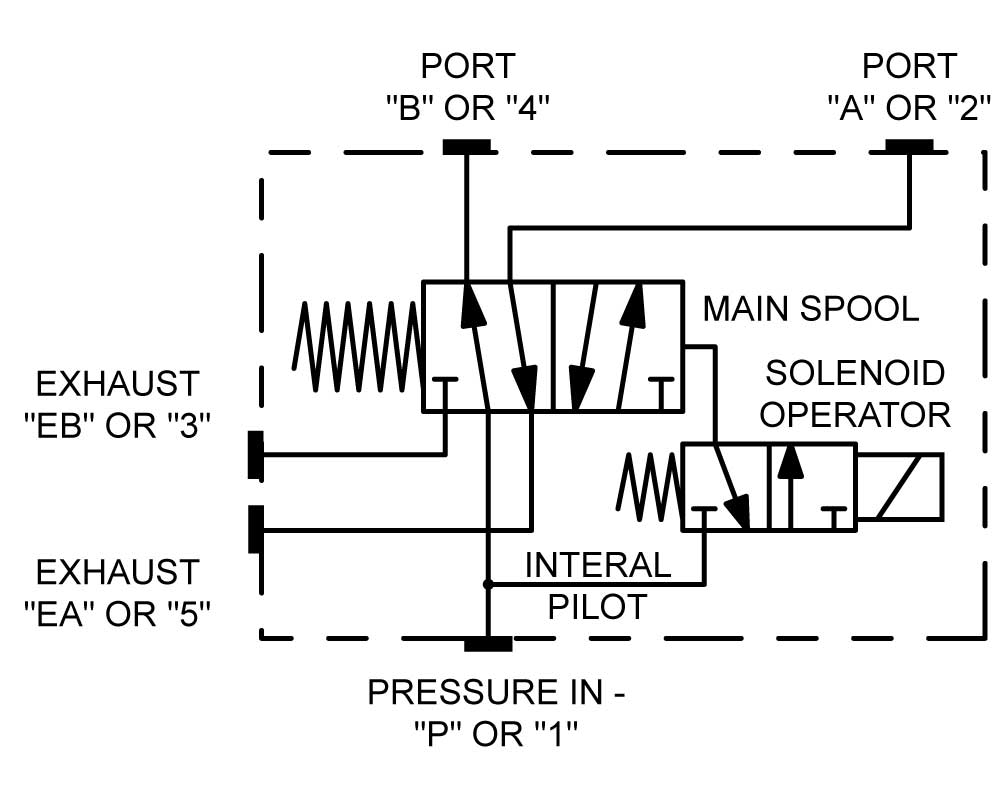

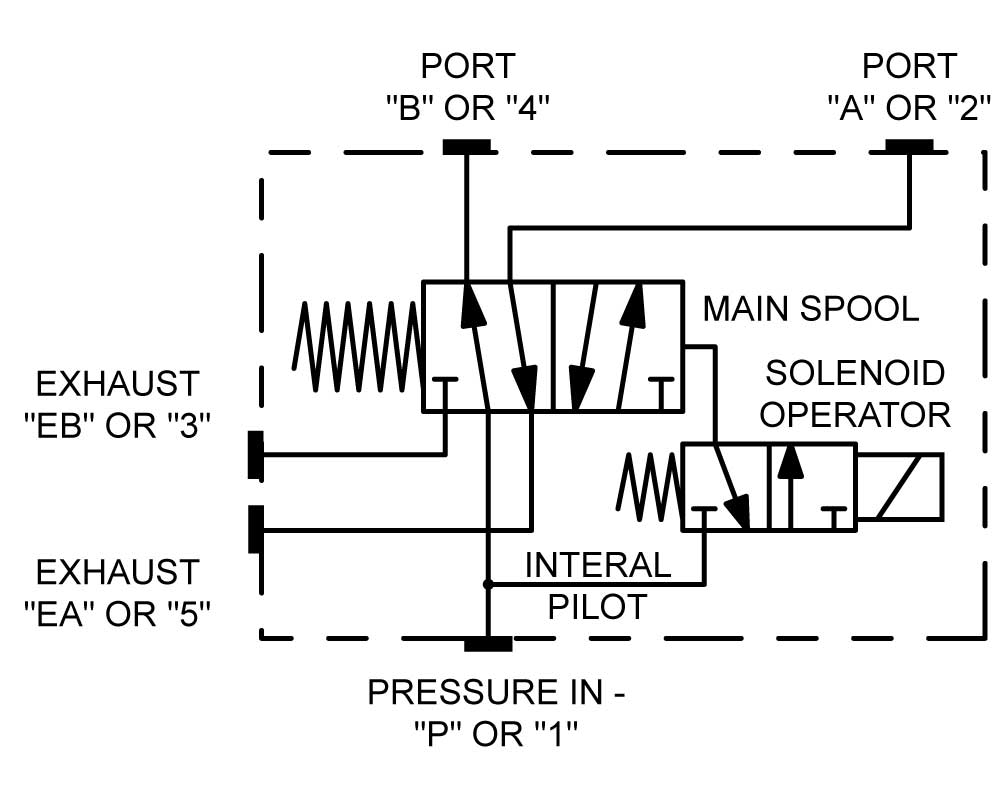

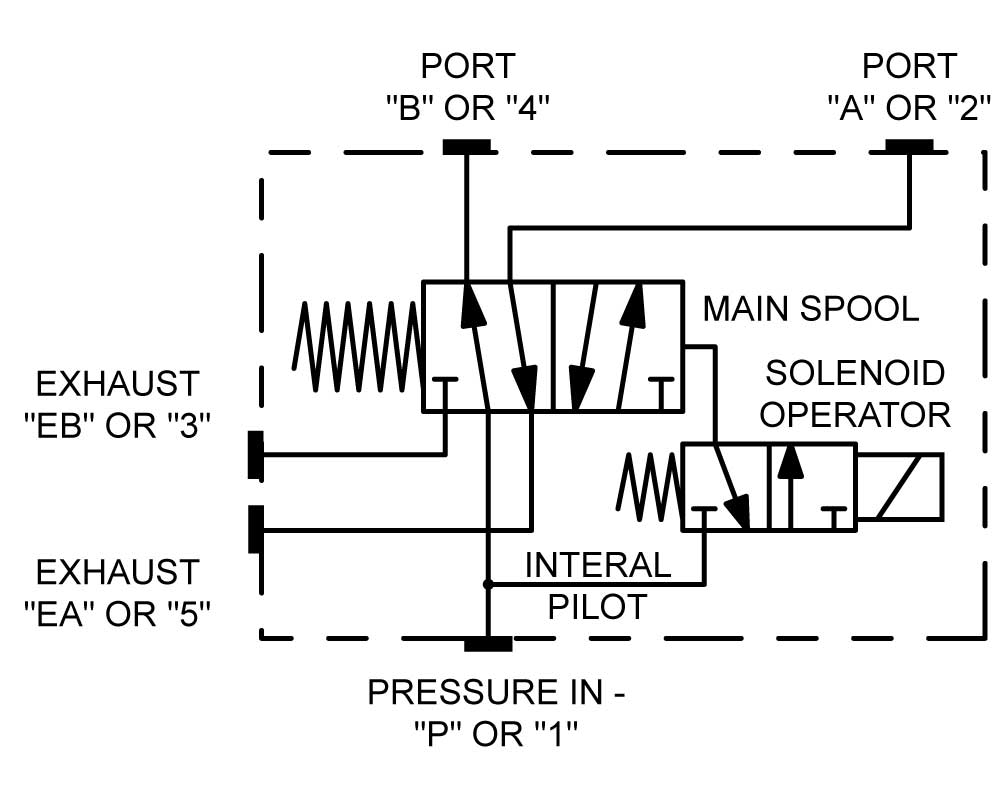

The inlet of gas to shift the spool can be derived from either internally or externally supplied gas.

Additional Considerations:

INTERNAL PILOT

EXTERNAL PILOT

Basic Operation:

When the coil is supplied with the correct power, a magnetic field is generated that pulls in a plunger. The plunger directs the inlet of gas to the end of the internal spool. At the same time, the solenoid exhaust through the stem is blocked, preventing the escape of gas and allowing pressure to build. The increase in the pressure on the end of the spool will shift the spool. Pressure of 25 psi for non-spring models and 50 psi for spring return or spring centered models is required for reliable spool shift (150 psi maximum). When the coil is de-energized, the plunger is returned to position via an internal spring which blocks the inlet of gas to the internal spool. At the same time, the solenoid exhaust is opened and the pressure at the end of the internal spool is allowed to exhaust.

The solenoid can be used as a simple 3-way valve that directs a gas source to the end of the spool or allows the gas from the internal spool to vent. The solenoid vent can be plumbed for direction of exhaust gases.

The return shift of the internal spool is controlled either by a spring, second solenoid, or various mechanical or piloted options.

The inlet of gas to shift the spool can be derived from either internally or externally supplied gas.

Additional Considerations:

- If the solenoid exhaust is blocked, thus preventing the reduction of pressure of the internal spool, the valve may not return or function properly.

- The exhaust of the solenoid can be pressurized to shift the internal spool, but caution must be used so adequate pressure differentials between the end chambers of the internal spool will allow the shifting of the internal spool. Testing must be performed to assure correct valve operation.

- Do not energize the coil while it is not on the solenoid stem. This will cause the coil to burn up and no longer create the needed magnetic field.

- Higher power then what the coil is rated for can be applied for short periods. This may however reduce the life span of the coil.

- When bench testing of internally piloted valves, adequate back pressure on the operating ports is required to allow sufficient pressure to shift the internal spool.