AAA Products International Inc.

7114 Harry Hines Blvd.

Dallas, Texas 75235

214-357-3851

7114 Harry Hines Blvd.

Dallas, Texas 75235

214-357-3851

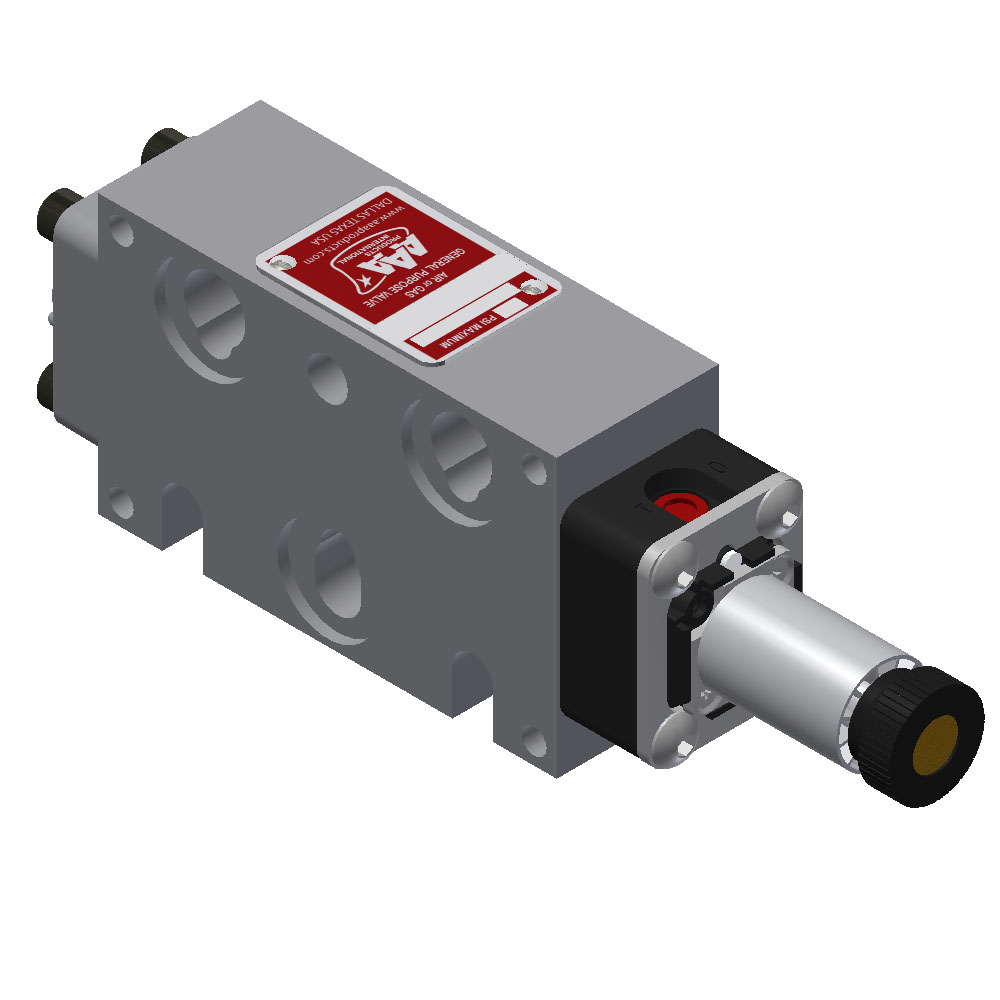

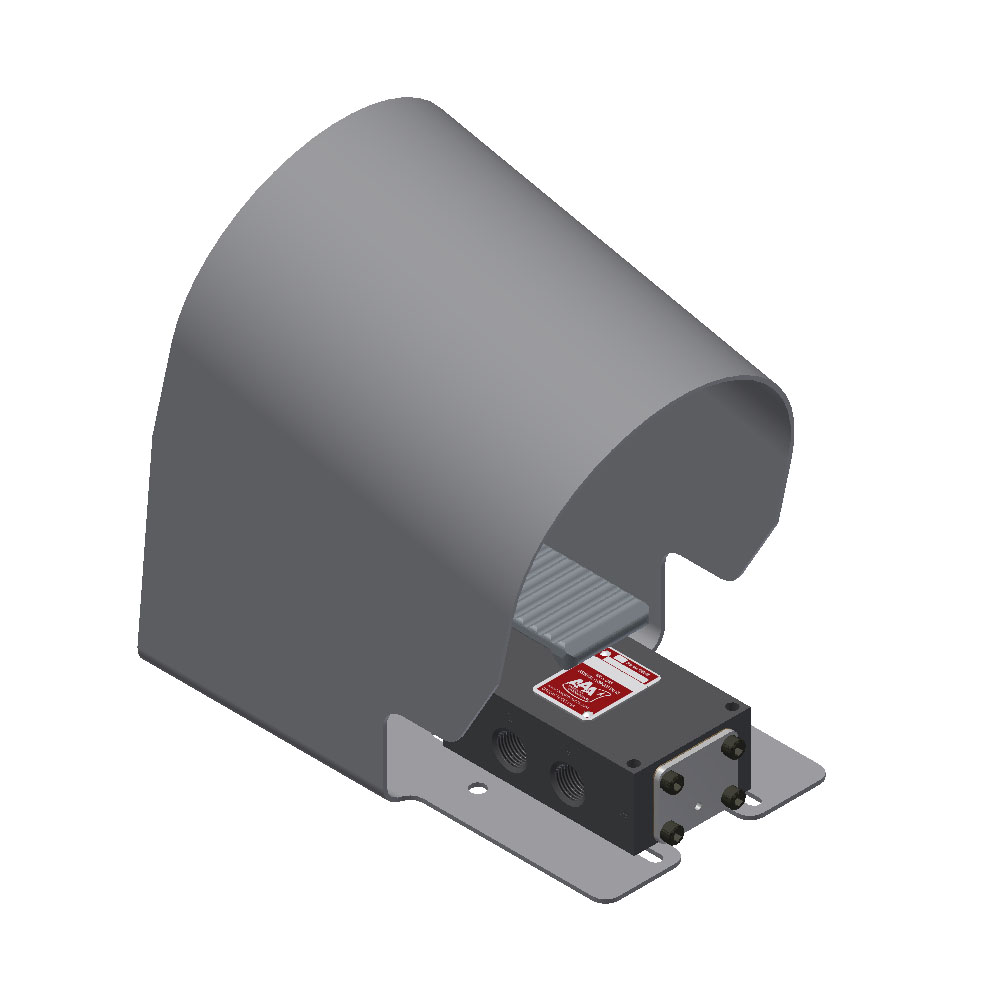

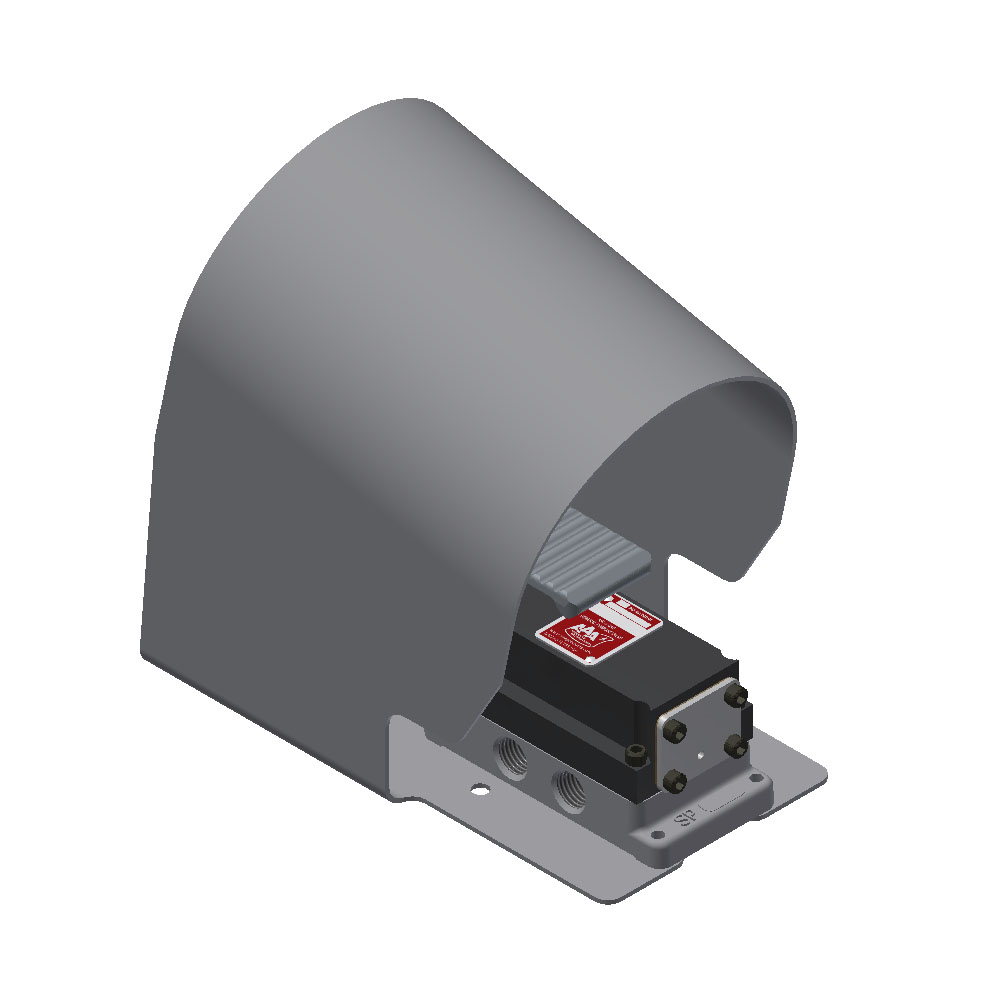

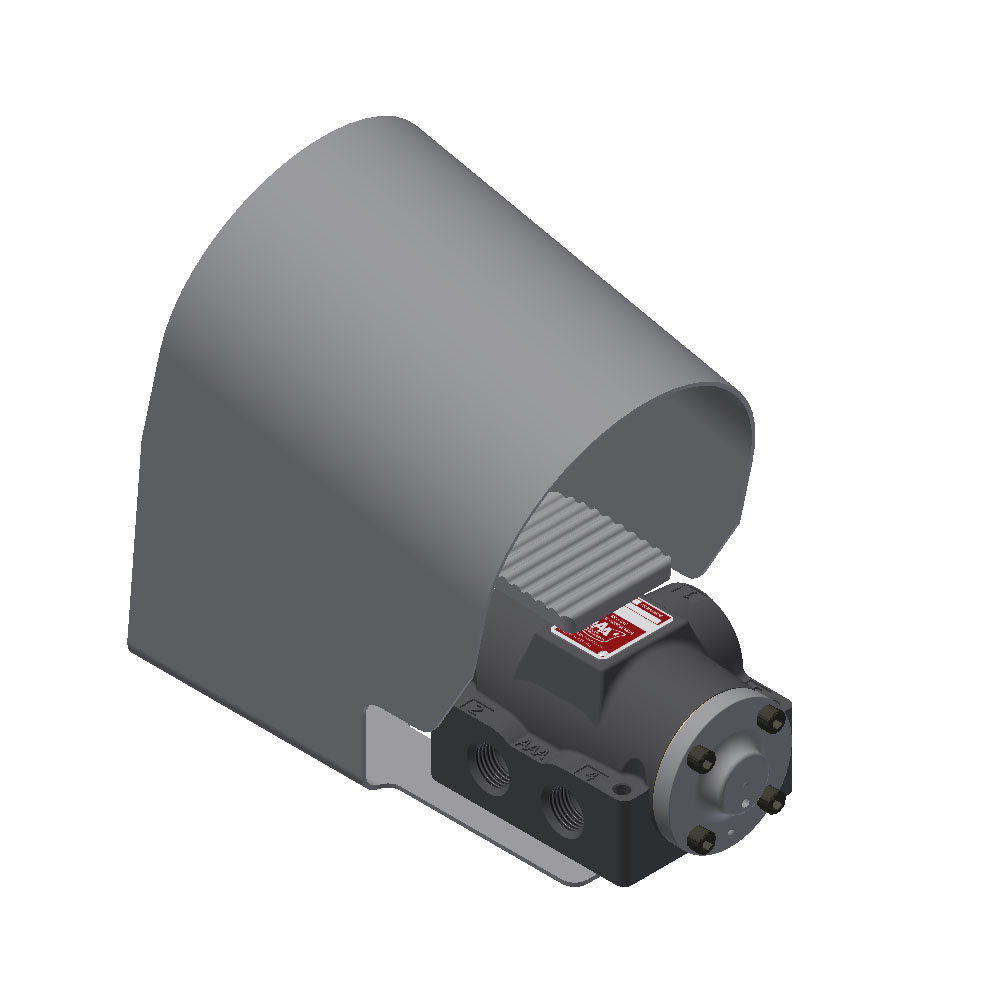

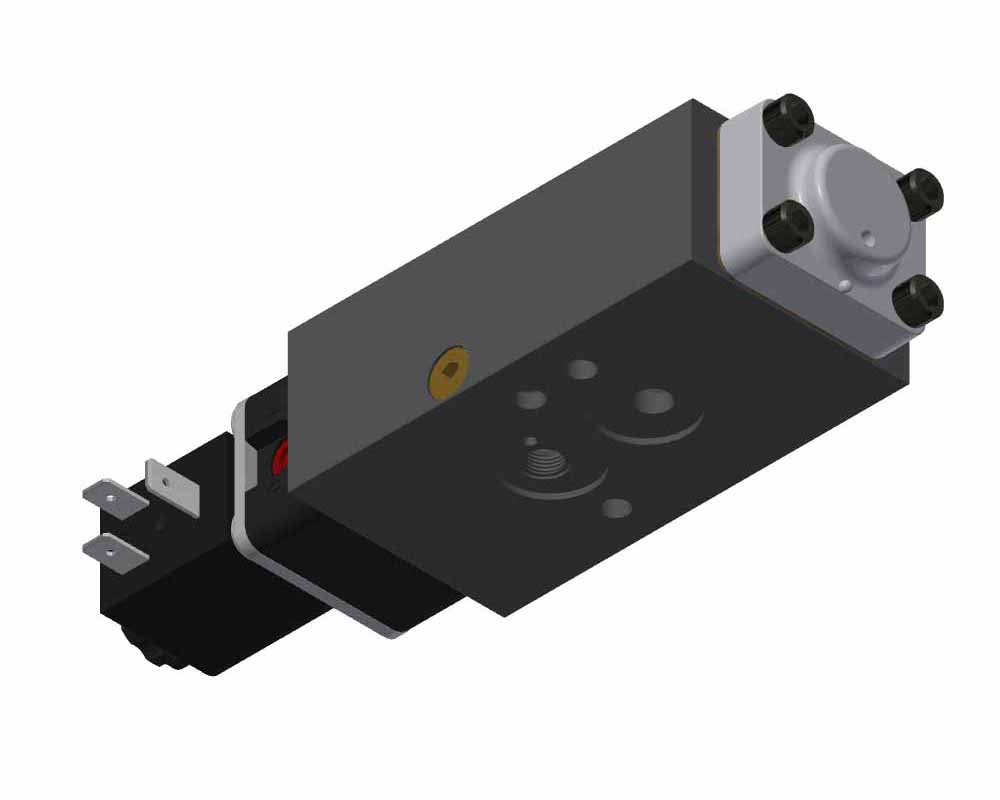

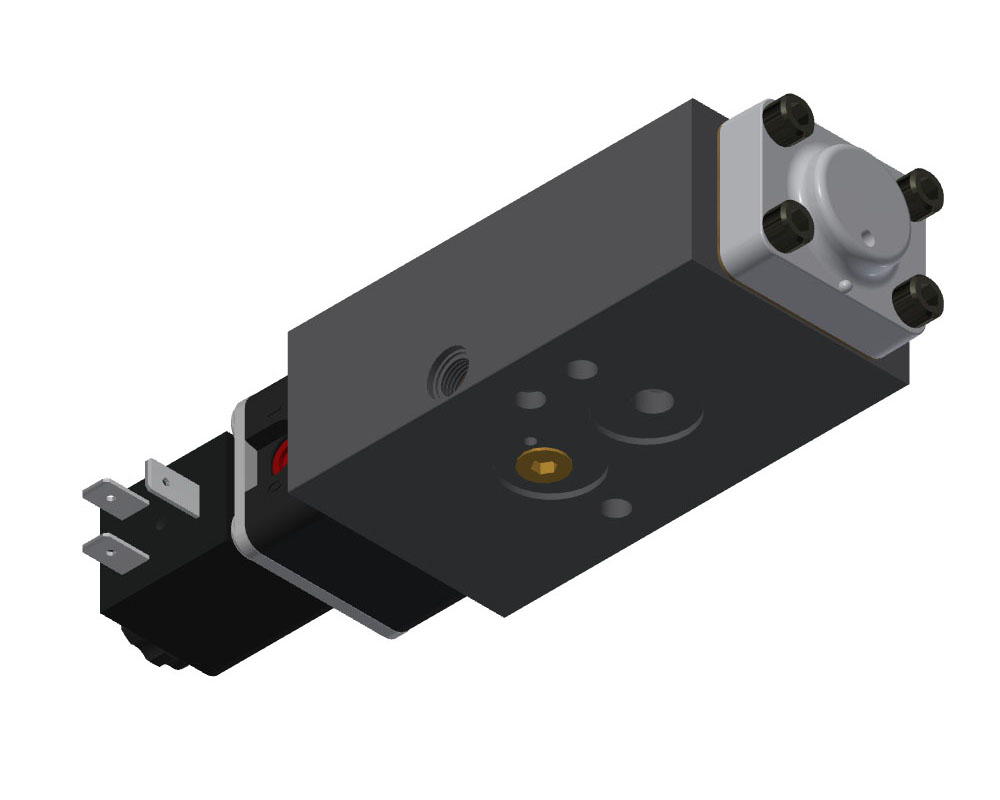

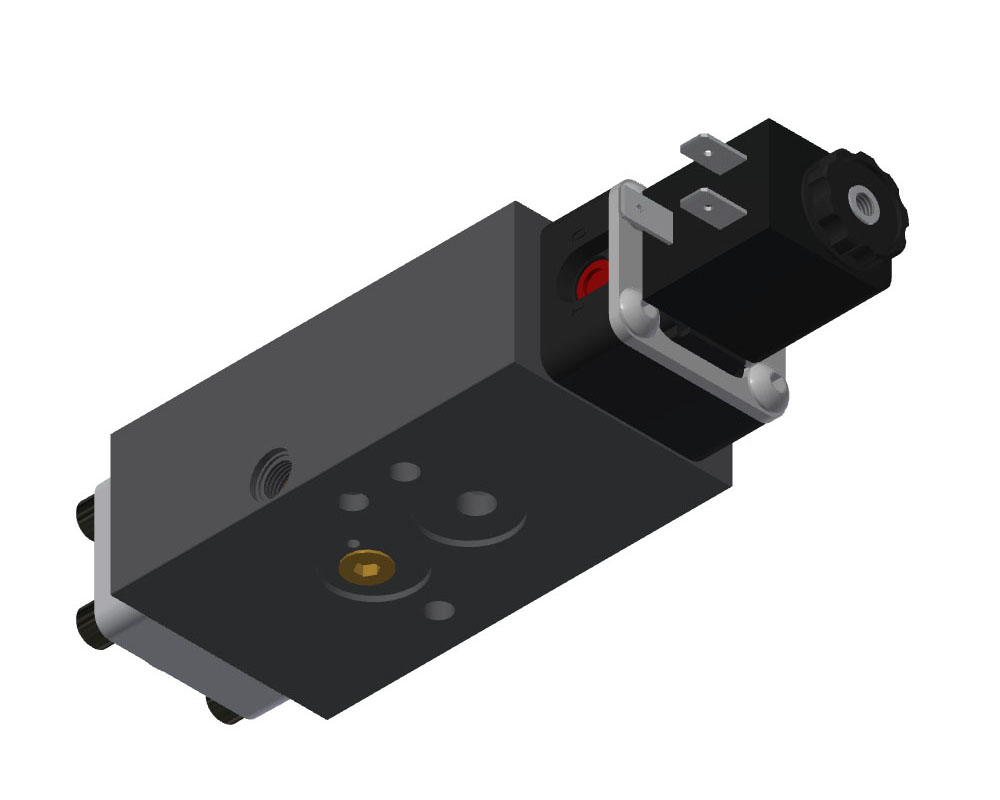

Data for 708V

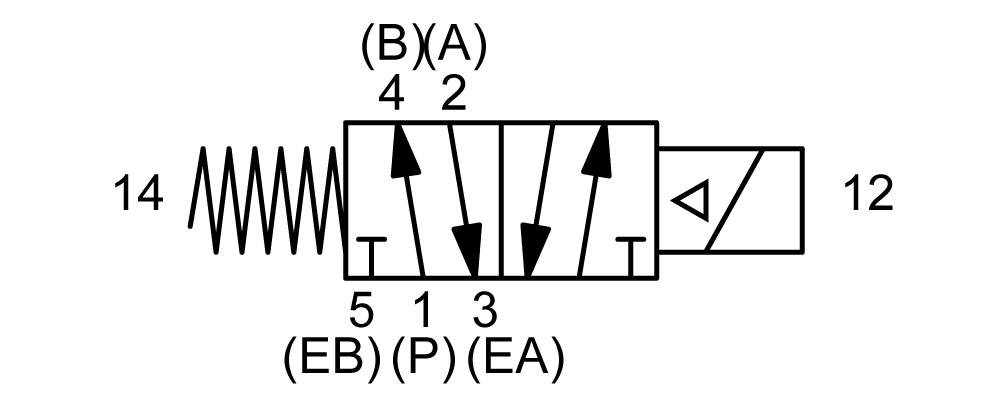

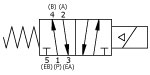

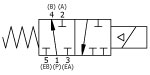

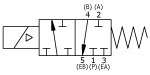

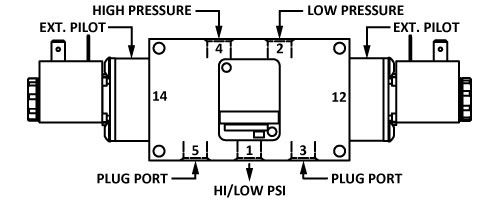

The 708V is a 1/4" NPTF side ported, 2 position, spring return, solenoid operated valve (solenoid coil not included). The spool is shifted by 80 to 150 psi internal pilot air derived from pressure in port 1 when the solenoid is energized. 80 to 150 psi must be maintained on port 1 to keep the spool shifted while the coil is energized. The spool is spring returned when the solenoid is de-energized. See additional information on solenoid valve operation. No solenoid coil is provided and 80 psi return spring. Last O-Ring is removed to venting of spool is through the exhaust port 5 not the end cap.

Details for 708V

Pressure: 80 to 150 psi on the main body of the valve when solenoid is internally piloted.

Vacuum: The valve cannot be vacuum operated when the solenoid is internally piloted.

Temperature: -20°F to 120°F ambient. Caution: If it is possible that the ambient temperature may fall below freezing, the medium must be moisture free to prevent internal damage or unpredictable behavior.

Mounting: The valve can be mounted in any orientation.

O-Rings: Viton.

Solenoid Seat: Viton.

Materials: Black anodized 6061-T6 aluminum body, hard anodized aluminum spool, A380 aluminum end cap, Viton solenoid seat, composite gaskets, steel fasteners.

Flow: 73.9 SCFM, 1.6 Cv

Repair Kit: ERKV-3.

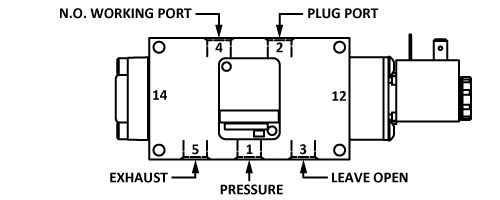

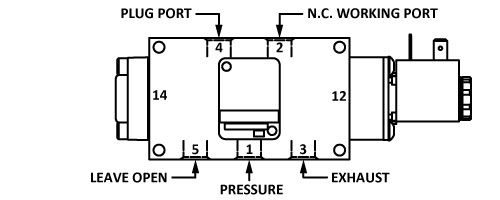

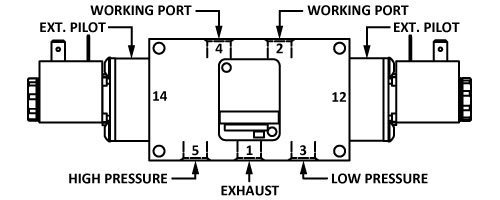

3-Way or 5-Way: This valve is basically 4-way, it must be configured for external pilot (Option 'Z') for 5-way service by using ports 2 or 4 as an inlet, or 3-way service by plugging the unused port 2 or 4.

Fluid Media: Soft seal models are made for air, vacuum, and gases compatible with component materials. They should not be used with liquids.

Vacuum: The valve cannot be vacuum operated when the solenoid is internally piloted.

Temperature: -20°F to 120°F ambient. Caution: If it is possible that the ambient temperature may fall below freezing, the medium must be moisture free to prevent internal damage or unpredictable behavior.

Mounting: The valve can be mounted in any orientation.

O-Rings: Viton.

Solenoid Seat: Viton.

Materials: Black anodized 6061-T6 aluminum body, hard anodized aluminum spool, A380 aluminum end cap, Viton solenoid seat, composite gaskets, steel fasteners.

Flow: 73.9 SCFM, 1.6 Cv

Repair Kit: ERKV-3.

3-Way or 5-Way: This valve is basically 4-way, it must be configured for external pilot (Option 'Z') for 5-way service by using ports 2 or 4 as an inlet, or 3-way service by plugging the unused port 2 or 4.

Fluid Media: Soft seal models are made for air, vacuum, and gases compatible with component materials. They should not be used with liquids.

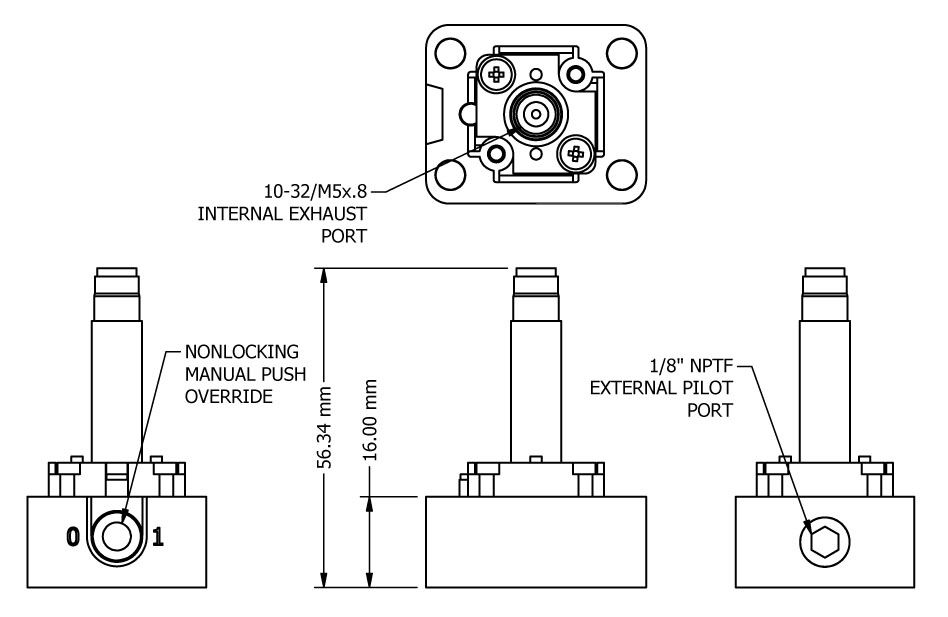

"E-Series" Operator - Standard

The standard operator is equipped with a non-locking manual push override and a 1/8" NPT external pilot port. For external pilot operation, the internal pilot pressure must be blocked and the plug must be removed and external pilot source must be provided (150 psi maximum). All operators have internally threaded exhaust stems. The thread fits 10-32 UNF or 5mm-0.8 fittings. Solenoid operator is equipped with a non-locking manual override on the side of the solenoid structure. To activate manual override, the inset red plunger must be depressed, red plunger returns when released. For replacement operators order ESPK which is a V-550-1 operator and an EMG3 gasket (individual operator components are not available).

Molding Material: Thermoplastic.

Ambient Temperature: -20°C to +50°C.

Internal Diameter Orifice: 1.3mm

General - Installation & Maintenance

Valves should be installed with reasonable accessibility for service. Exercise care in keeping tubing lengths to a minimum. Plumbing should be free of contamination. Pipe joint compound should be used sparingly applied only to the thread, never the valve body. Over tightening of pipe threads can fracture the joint causing leaks or failure. Protect the valve from exposure to extreme temperatures, dirt and moisture to maximize life.

Bulletin A-113: Operating & Maintenance Instructions.

Installation: Valve Fitting Installation.

WARNING:These products can expose you to chemicals which is(are) known to the State of California to cause cancer or reproductive harm. For more information, go to www.P65Warnings.ca.gov. Contact us for specific chemicals or materials used in a product.

WARNING:These products can expose you to chemicals which is(are) known to the State of California to cause cancer or reproductive harm. For more information, go to www.P65Warnings.ca.gov. Contact us for specific chemicals or materials used in a product.

Bulletin A-113: Operating & Maintenance Instructions.

Installation: Valve Fitting Installation.

WARNING:These products can expose you to chemicals which is(are) known to the State of California to cause cancer or reproductive harm. For more information, go to www.P65Warnings.ca.gov. Contact us for specific chemicals or materials used in a product.

WARNING:These products can expose you to chemicals which is(are) known to the State of California to cause cancer or reproductive harm. For more information, go to www.P65Warnings.ca.gov. Contact us for specific chemicals or materials used in a product.

General - Lubrication, Standard

All valves are pre-lubricated at the factory using Magnalube-G Teflon based all purpose grease. Valves are suitable for, and perform best in a non-lube service. For long life, use an air line filter/lubricator installed no further than 10-ft. from the valve. The filter should be rated 25 pm or finer. Use a good grade of petroleum base lubricating oil no heavier than SAE 10W. DO NOT OVER-LUBRICATE. This could cause the spool to stick. CAUTION! Do not use questionable fluids in air line lubricators. Do not use petroleum oil with detergent additives. Detergents, volatile or aromatic fluids may swell rubber seals in valves and cylinders. Never use cooking or vegetable oil as a lubricant. When cleaning AAA valves after extended service, lubricate the valve spool with AAA high film strength grease, or, use O-ring grease which is usually available from supply houses which sell O-rings. Magnalube-G is included in all valve repair kits for proper valve maintenance. If an additional amount of Magnalube-G grease is required, a 0.75 ounce tube is available under part number VGK-3. Never use any kind of oil, cup grease, or automobile chassis lubricant.

The shelf life of Magnalube-G regularly lasts for 10+ year intervals in closed packaging due to the extremely long operating life of the Elastomer-PTFE gelling agent and premium parafiinic mineral base oil. If the valve is stored for over 2 years, then a small reapplication of grease is suggested.

Magnalube-G Technical Document

Magnalube-G MSDS Document

The shelf life of Magnalube-G regularly lasts for 10+ year intervals in closed packaging due to the extremely long operating life of the Elastomer-PTFE gelling agent and premium parafiinic mineral base oil. If the valve is stored for over 2 years, then a small reapplication of grease is suggested.

Magnalube-G Technical Document

Magnalube-G MSDS Document

An alternative grease for low temperature application, refer to Dow-55 grease.

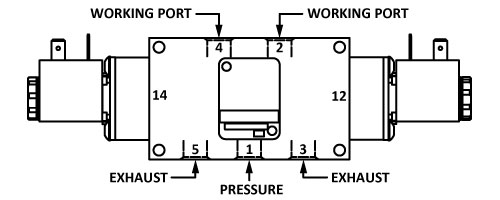

3-WAY N.O. APPLICATION

3-WAY N.O. APPLICATION 3-WAY N.C. APPLICATION

3-WAY N.C. APPLICATION

4-WAY APPLICATION

4-WAY APPLICATION

5-WAY APPLICATIONS

5-WAY APPLICATIONS